Industrial sheds are large-span steel structures specifically designed for various industrial applications.

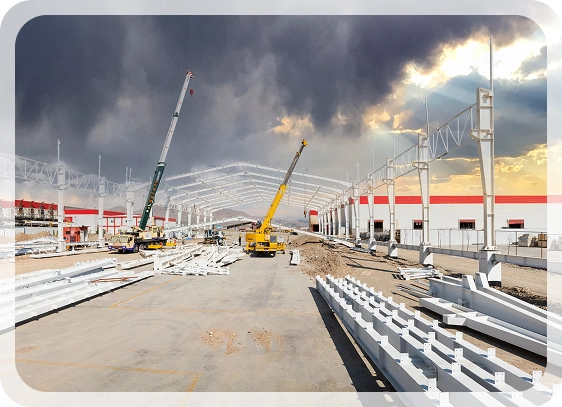

Mammut industrial sheds are steel structures with pitched roofs, specifically engineered to create large, column-free spaces. Compared to traditional buildings, these structures offer faster construction times and greater design flexibility.

Their applications are highly versatile and include factories, warehouses, production halls, as well as agricultural uses such as livestock and poultry farms.

The construction process of an industrial shed involves several key stages:

Maintenance primarily focuses on protecting the structure from corrosion. When purchasing an industrial shed, it is essential to consider the quality of materials, the construction methodology, and the long-term maintenance requirements.

If you would like to receive a free professional consultation, please fill in your information in the form below. Our experts will contact you as soon as possible to provide the specialized services you need.

Industrial sheds are categorized into various types based on their construction methods, each designed to meet specific functional requirements.

In addition to these types, steel, concrete, and prefabricated sheds are also recognized as general categories, defined by the materials and construction techniques employed.

A plate girder shed is a type of steel structure primarily constructed using large steel beams and plates. These sheds are widely used in industrial facilities, warehouses, factories, and large commercial buildings.

Their construction must comply with national building codes and engineering standards. The design is optimized to withstand various loads such as wind and seismic forces. Key structural components are fabricated by cutting steel plates and assembling them using welding or bolted connections, resulting in a highly durable and safe structure.

Truss industrial sheds—also known as lightweight sheds—are among the most common and practical construction methods for industrial buildings. Featuring unique roof geometries such as arched or gable-shaped designs, these sheds enable uniform load distribution across the structure.

Truss systems include both tension and compression members, which are designed and controlled according to national building regulations. For large-span trusses (e.g., over 12 meters), a camber may be added to compensate for deflection under load. Additionally, compression members in braced frames (often made of trusses) must account for effective length factors, which influence their structural resistance. Connections between truss members—whether welded or bolted—must be executed in compliance with structural code requirements (such as Chapter 10 of the national building code).

UBM (Ultimate Building Machine) sheds are made from galvanized steel sheets that are joined using a special machine called a “Seamer.” While this system allows for quick, frameless construction, it also poses structural limitations. Due to thermal expansion, contraction, and wind-induced vibrations, there is a risk of sheet separation over time.

UBM sheds are best suited for structures with spans under 30 meters and are not ideal for environments with high humidity, heavy rainfall, or snow loads. A key drawback is the use of spray-applied insulation, which is flammable, prone to absorbing contaminants, and cannot be sanitized—leading to increased maintenance requirements and overall lifecycle costs.

The cost of an industrial shed is calculated on a project-specific basis, as each structure has unique requirements depending on its dimensions, location, purpose, and the materials used. To accurately estimate the cost, several key parameters must be considered:

Type and Thickness of Steel Sheets

The choice of sheet material—such as black steel, galvanized steel, or Aluzinc—significantly impacts the total cost.

Roof and Wall Cladding

Depending on the shed’s intended use, cladding may include sandwich panels, plain steel sheets, or polycarbonate sheets, each varying in cost and performance.

Height and Number of Frames

Taller sheds often require more robust bracing systems and may be equipped with overhead cranes, both of which increase the cost.

Project Location

Transportation costs and on-site installation challenges—especially in mountainous or remote areas—can also affect the final price.

Engineering design, construction quality, and the expertise of the installation team play a critical role in the success of your project.

At Mammut Structures & panel, all designs are developed according to international standards using advanced software tools such as SAP2000 and Tekla Structures. Components are fabricated with CNC machinery and undergo a multi-stage quality control process, ensuring precision, durability, and long-term structural performance.

The installation team at Mammut is comprised of highly trained professionals with a proven track record of delivering over 500 industrial projects across Iran and neighboring countries.

In addition to technical excellence, Mammut offers highly competitive pricing—thanks to high-efficiency production lines, top-grade materials, and a direct-to-customer model that eliminates intermediaries.

In Mammut Structures & panel, the design and construction of industrial sheds are carried out entirely based on the project’s needs and the client’s specific drawings. The selection of span, length, effective height, and overhead crane capacity is made in accordance with the National Building Regulations, Chapter 10, and the AISC method to ensure both safety and cost-effectiveness. The steel structure is built using bolted connections and undergoes strict quality control (MT and PT testing). It is also possible to design for specific applications such as cold storage, agricultural, or industrial sheds.

Pre-purchase technical consultation helps buyers make the best decision based on climatic conditions, budget, and future capacity planning.

The duration of design, production, and delivery of Mammut industrial sheds follows international standards such as AISC 360 and ANSI/AISC 303. This approach ensures that projects are delivered with high quality and on time.

The estimated timeline from design to installation of the industrial shed is as follows (total estimated duration: 32 to 54 working days – approximately 6 to 11 weeks).

|

Phase

|

Estimated Duration

|

Description

|

|---|---|---|

|

Engineering Design

|

7–10 working days

|

Includes structural calculations and preparation of execution drawings in compliance with AISC 360 and ANSI/AISC 303 standards.

|

|

Material Procurement

|

5–12 working days

|

Depends on market availability and the type of steel required.

|

|

Steel Structure Fabrication

|

10–15 working days

|

Welding performed according to AWS standards with strict quality control.

|

|

Painting and Final Coating

|

3–5 working days

|

Application of corrosion-resistant industrial coatings.

|

|

Transportation & Installation

|

7–12 working days

|

Depends on the project's location and site conditions.

|

Mammut Structures & panel, utilizing advanced production lines and experienced teams, enables the delivery of industrial sheds within shorter timeframes. In urgent projects, with proper coordination and precise scheduling, the delivery time can be minimized.

To receive an accurate delivery estimate and expert consultation, please contact our specialists or fill out the consultation form.Mammut Structures & panel

Frequently Asked Questions

An industrial shed is a type of steel structure used in various sectors such as manufacturing, warehousing, factories, workshops, industrial livestock farming, and cold storage facilities.

These sheds are designed based on industrial requirements in terms of dimensions, height, and ventilation. Due to their high structural strength, cost-effective construction, and fast installation, they are a suitable choice for both industrial and commercial projects.

Industrial sheds are lighter, more durable, and faster to install compared to concrete structures.

They also offer greater flexibility for future expansion and design modifications.

Mammut Steel Structure utilizes high-quality steel sheets and adheres to international standards, providing enhanced strength and durability through advanced welding technologies.

Ask ChatGPT

Yes, Mammut Steel Structure offers the design and construction of industrial sheds based on the specific needs of its clients.

The delivery and installation time varies depending on the shed’s dimensions and design; however, the project timeline is defined in advance and executed in the shortest possible time.

Mammut industrial steel sheds are used as large, column-free spaces for industrial operations, manufacturing, warehousing, and training workshops.

Mammut industrial steel sheds, with their engineered design and use of high-quality materials, offer greater strength and durability, enabling wide-span coverage without the need for additional interior columns.

By contacting shed suppliers and consultants, you can receive detailed information regarding pricing, construction time, and delivery schedule.

Installation requires proper site preparation and obtaining the necessary permits, which are the responsibility of the client. Maintenance includes periodic inspections of the structure and minor repairs if needed.

"*" indicates required fields