The construction process of plate girder steel structures at leading companies such as Mammut Structures & panel follows a fully engineered and controlled pathway, based on international standards. This ensures both structural quality and on-time delivery. The main stages of constructing a plate girder shed are as follows:

- Project needs assessment and land measurement

- Structural design using SAP2000, Etabs, and Tekla software

- Calculation of live and dead loads based on climate and usage

- Precision cutting of steel sheets using CNC machines

- Beam welding with Submerged Arc Welding (SAW) and weld quality control

- Assembly of columns, rafters, and other components in the factory

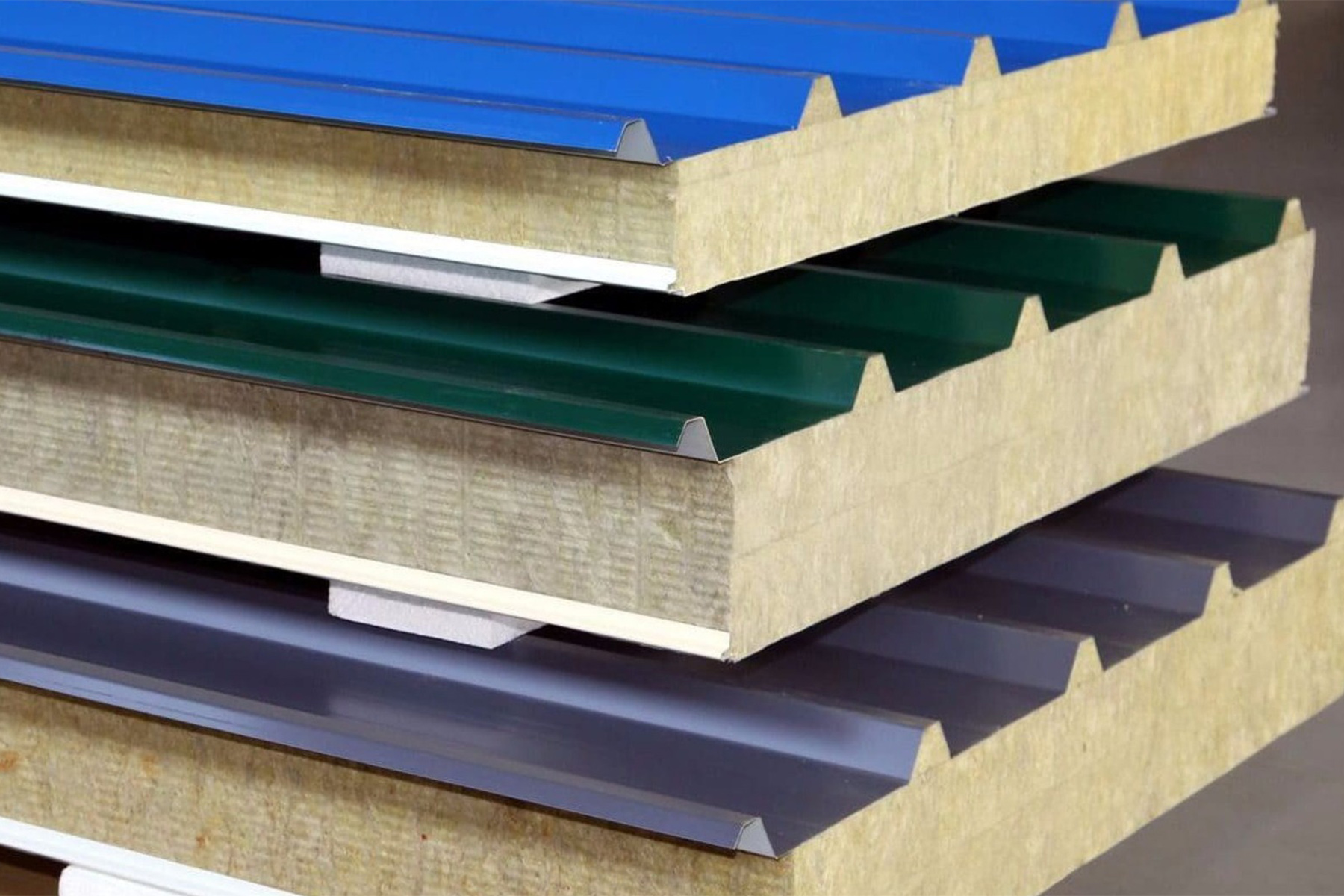

- Industrial painting or hot-dip galvanizing for corrosion protection

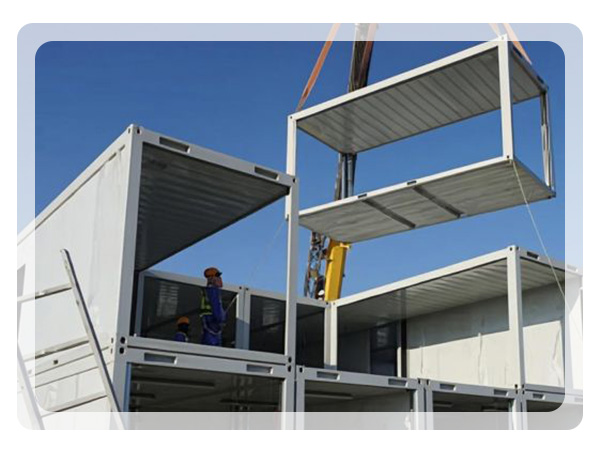

- Transportation and on-site installation using cranes and bolted connections

Finally, a thorough quality inspection is conducted before commissioning to ensure the shed is ready for handover. This process guarantees structural accuracy and long service life.