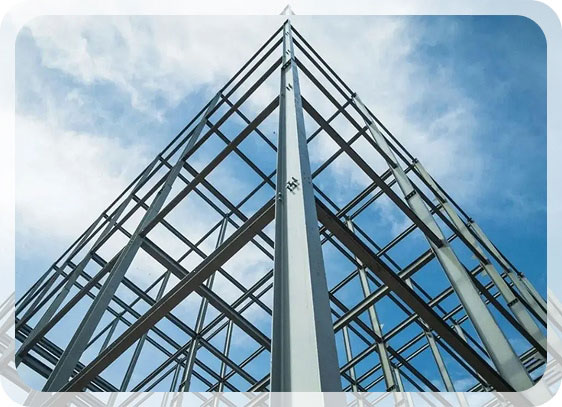

The steel framework, as one of the most significant developments in the construction industry, has had a profound impact on the design and execution of structures.

The use of steel as a construction material began in the early 20th century and, after World War II, with easier access to steel and a reduction in its price, the use of steel structures saw a significant increase. Today, steel construction has gained considerable attention from engineers and architects.

The steel structures of Mammut Structure Company started operations in 2003 (1382 in the Iranian calendar). Today, the company holds the record for an annual production capacity of 50,000 tons and has completed over 2,500 projects both domestically and internationally. These projects include industrial halls, power plant structures, oil and gas facilities, petrochemicals, pipe racks, road and rail bridges, steel frameworks for hotels, hospitals, residential and office buildings. As a market leader, Mammut Structure strives to fulfill its responsibility in design, engineering, capacity, and construction quality to the highest standard.

We are proud to be at the forefront of the steel structure industry in Iran, contributing to the preparation, development, and implementation of Iranian National Standards 6-3834, 5-3834, 3834-2, and 3834-1. We have also been granted the right to use the Iranian Standard mark on Mammut-produced products by the Iranian Supreme Council of Standards.

If you would like to receive a free professional consultation, please fill in your information in the form below. Our experts will contact you as soon as possible to provide the specialized services you need.

Steel Building Framework is one of the most practical subcategories of steel structures. Simply put, the steel framework of a building refers to the steel structures that are seen at the initial stages of constructing a building. These structures are used to construct buildings of various sizes and with different functions. The main role of the steel framework in a building structure is to create strong foundations and columns upon which the subsequent construction phases are carried out. In other words, this structure forms the skeleton of the building and determines its strength.

Commercial and Office Buildings:

The use of steel structures in commercial and office buildings is very common because of the fast construction process and the ability to create large open spaces without interior columns.Bridges and Transportation Structures:

Structural steel is widely used in the construction of bridges and other transportation infrastructure due to its high resistance to compressive and tensile forces.Sports and Exhibition Halls:

Steel structures are frequently used in the construction of sports arenas and exhibition halls because they allow for the creation of wide, unobstructed interior spaces.

The building frame serves as the main structural system that supports and transfers all dead and live loads to the ground. Proper design and precise execution of the steel frame are critical, as they significantly impact the structure’s resistance against external forces such as earthquakes, wind, and other loads.

Benefits of Consulting with Mammut Experts

The construction stages of a welded structural steel frame are carried out directly at the final project site. The steel beams and columns are cut and then welded together on location. If the welding is not performed correctly, the structural frame may be weakened by natural forces and could ultimately lead to building failure.

Advantages

It is recommended to use welded connections for structures subjected to torsional forces. Since there are no additional bolts and nuts in this type of structural steel system, the final construction has a more uniform and aesthetically pleasing appearance.

Applications

This type of structural system is commonly used for buildings with smaller floor areas. In general, welded steel frames are recommended for buildings with simple architectural plans and straightforward designs.

The construction of a welded structural steel frame is carried out directly at the final project site. The steel beams and columns are cut to size and welded together on-site. If the welding is not performed correctly, the structural frame may weaken over time due to environmental factors, potentially leading to structural failure.

Advantages

It is recommended to use welded connections for structures subjected to torsional forces. Since this type of structural system does not require additional bolts and nuts, the final structure offers a more seamless and aesthetically pleasing appearance.

Applications

Welded steel frames are typically used in the construction of smaller-scale buildings. In general, they are recommended for buildings with simple architectural layouts, where a straightforward and cost-effective structural system is preferred.

Frequently Asked Questions

A structural steel frame is a metal framework used as the foundation for buildings. Its advantages include high strength, fast construction, and suitability for high-rise buildings.

A steel frame is lighter, faster to construct, and more recyclable, whereas a concrete frame is heavier and requires more time to complete.

A structural steel frame serves as the main framework of a building, providing strength and stability to the entire structure.

Steel frames are generally lighter, quicker to install, and capable of bearing heavy loads.

It can be ordered through specialized manufacturers. After the execution drawings are approved, the typical production and delivery time ranges from 5 to 10 weeks.

A structural steel frame requires precise installation and regular inspections to prevent corrosion and structural damage.

"*" indicates required fields