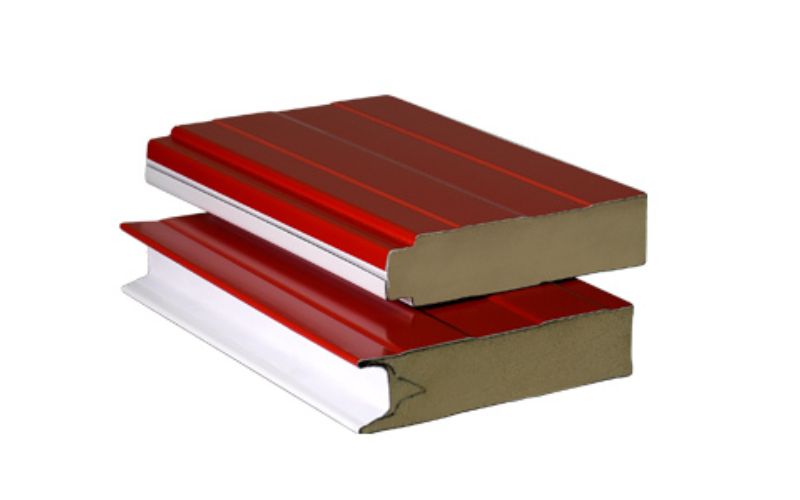

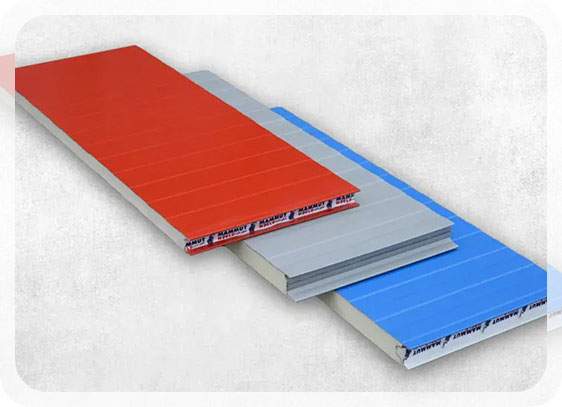

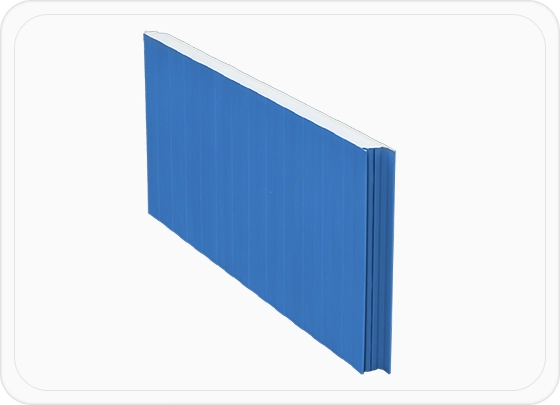

Wall Sandwich Panels are high-performance prefabricated materials used in industrial, cold storage, and commercial buildings. Made of two metal sheets (Aluzinc or Galvanized) and a thermal insulation core (Polyurethane or Rock Wool), these panels offer excellent strength, energy efficiency, and fire resistance.

Available in flat, interlocking, and decorative profiles, Sandwich Wall Panels are lightweight, quick to install, and built to last — making them a smart choice for modern wall cladding and space partitioning needs.

If you would like to receive a free professional consultation, please fill in your information in the form below. Our experts will contact you as soon as possible to provide the specialized services you need.

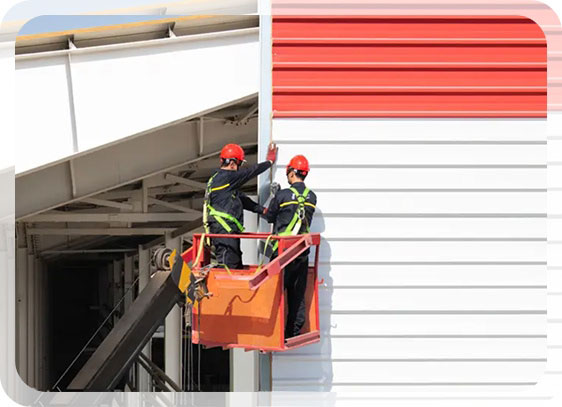

If you’re seeking a durable, lightweight, and energy-efficient solution for cladding industrial buildings, warehouses, cold storage facilities, or production halls, buying Wall Sandwich Panels from Mammut is a strategic investment. Backed by over 30 years of large-scale manufacturing experience, Mammut’s Wall Sandwich Panels are engineered using advanced technologies to meet the specific needs of today’s construction sector.

As a leading Wall Sandwich Panel manufacturer in the Middle East, Mammut offers products designed with high thermal insulation (Polyurethane or Rock Wool core), interlocking joint systems for airtight sealing, and corrosion-resistant coatings that withstand moisture, UV, and harsh climates.

Whether you’re a project manager, procurement officer, or construction investor, Mammut delivers key advantages:

Choose a Wall Panel producer trusted across the region. Purchase Wall Panels from Mammut for reliable quality, energy savings, and long-term performance that meets both technical and economic demands of your project.

|

Column One

|

|

|---|---|

|

Effective Width (mm):

|

1140 mm

|

|

Length (m):

|

From 2 m to 13.60 m (according to order)

|

|

Polyurethane Foam Density (ASTM 1622):

|

40 ± 2 kg/m³

|

|

Fire Class (DIN 4102):

|

B1-B2-B3

|

|

Coating Type:

|

PIR - PUR

|

|

Top Sheet Thickness (mm):

|

0.7, 0.5, 0.4

|

|

Bottom Sheet Thickness (mm):

|

0.7, 0.5, 0.4

|

|

Fixed Width (mm):

|

1160 mm

|

|

Foam Thickness (mm):

|

150, 125, 100, 80, 60, 50, 40, 30

|

|

Sheet Type:

|

Aluzinc – Galvanized – Aluminum

|

For professional buyers, understanding the different types of Wall Sandwich Panels is key to making informed and cost-effective choices. Depending on the project type, climate conditions, aesthetic goals, and technical requirements, selecting the right panel significantly impacts structural performance and long-term savings. Below is a detailed introduction to the main types of Wall Sandwich Panels, each designed for specific uses and applications.

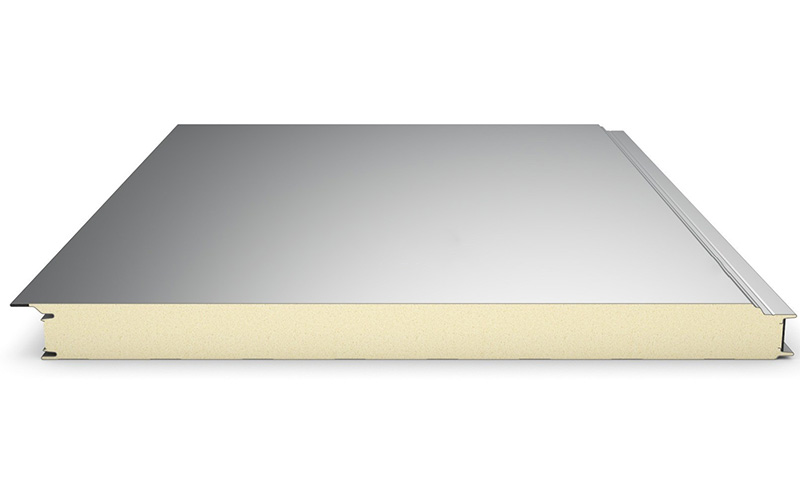

The flat Wall Panel (DNS) is ideal for projects requiring a smooth, minimalist finish. Commonly used in pharmaceutical, hygienic, or industrial facilities, this panel features corrosion-resistant outer sheets (typically Aluzinc or galvanized steel) and a core made of polyurethane or rock wool. Fast installation, complete sealing, and excellent hygiene make it suitable for clean rooms, internal partitions, and moisture-controlled environments.

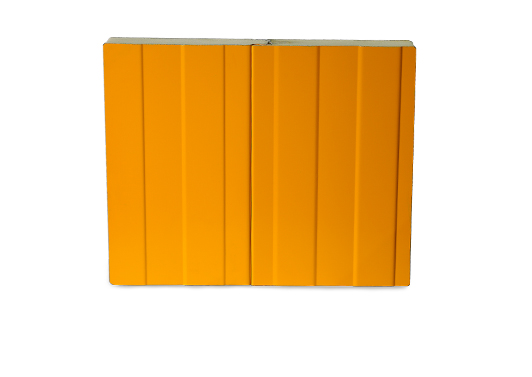

The ribbed DND model offers enhanced mechanical strength and visual appeal through its corrugated surface design. It’s the preferred wall panel for cold storage units and external façades exposed to harsh weather. The use of polyurethane ensures superior thermal and acoustic insulation. While the cost of this Wall Sandwich Panel may be slightly higher than flat models, its durability under severe conditions justifies the investment.

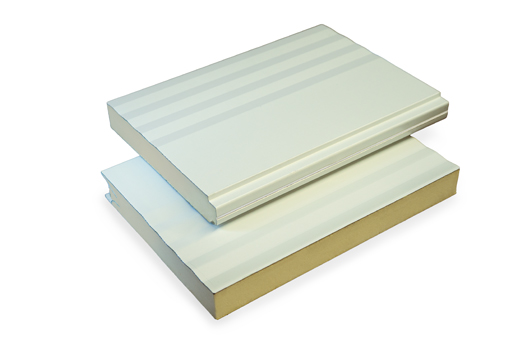

The Micro-Ribbed Sandwich Wall Panel features fine textures and shallow grooves on the outer surface, making it an optimal choice where industrial aesthetics and high performance are both required. Ideal for warehouses, showrooms, and logistics centers, it uses UV-resistant Aluzinc and polyurethane core, ensuring excellent insulation. Fast and efficient installation further enhances its value in time-sensitive projects.

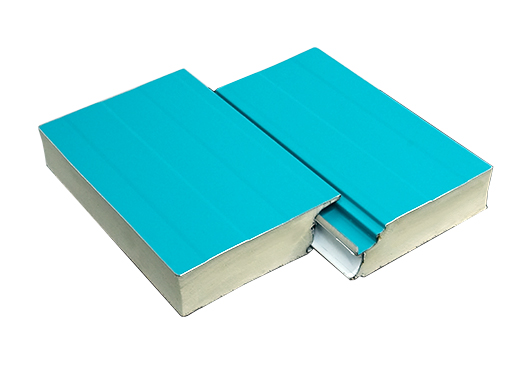

RPO panels combine architectural elegance with structural integrity. Fasteners are hidden behind the panel, creating a seamless visual finish — perfect for office buildings, commercial centers, and exposed façades. The system uses high-strength, corrosion-resistant steel sheets and polyurethane insulation, ensuring both energy efficiency and a clean appearance. Specialized interlocking systems allow for quick and secure installation.

In high-risk environments such as electrical rooms, chemical facilities, or production halls, fire-resistant Wall Sandwich Panels are essential. These panels feature a PIR or rock wool core with certified fire resistance up to 2 hours. The external sheets are treated for high-temperature tolerance, minimizing deformation during fire exposure. Designed in compliance with international safety standards, they significantly reduce both human and financial risks.

Mammut Structures offers a wide range of Wall Sandwich Panel applications, from industrial construction to commercial development. With flexible customization, professional technical support, and proven manufacturing quality, we provide reliable Wall Sandwich Panel sales solutions across the Middle East and beyond.

In industrial, warehousing, or large-scale construction projects, the Wall Sandwich Panel price is not just a number—it reflects a series of technical decisions, environmental conditions, and material choices. To make an optimal and cost-effective decision for your project, understanding the key factors affecting the cost of Wall Sandwich Panels is essential. Here are the main elements that influence the price of Wall Panels:

Choosing to buy Wall Sandwich Panels from a trusted manufacturer delivers the best value when price, performance, and durability align at an optimal level. At Mammut, we provide transparent and precise pricing calculations based on your actual project specifications—ensuring a clear and confident path to purchase.

Purchasing Wall Sandwich Panels from Mammut is more than a simple procurement decision—it’s a smart investment in energy efficiency, structural longevity, and faster project delivery. With over 30 years of industry-leading experience as a Wall Sandwich Panel manufacturer, Mammut is committed to helping you select the right panel solution for your specific application—whether for industrial, commercial, or construction projects.

Our technical experts are available at every step to ensure you make the most informed and cost-effective decision. With Mammut, the process of buying Wall Sandwich Panels becomes simpler, faster, and far more reliable. Contact us today for expert consultation and benefit from working with one of the largest and most trusted Wall Sandwich Panel producers in the Middle East.

Advantages of Consulting with Mammut Experts

We believe in transparent pricing. Here’s what determines the final cost of Wall Panel installation:

Submit your project details and receive a personalized cost breakdown within 24 hours.

This type of panel is produced and installed in separate sections, with gaps between each panel. These gaps are usually covered with special connectors and profiles, making this type of panel suitable for areas that require ventilation or passage of cables and equipment.

Due to the defined spacing, non-continuous panels provide greater flexibility in project design and structure. They are mostly used in interior walls or places that require frequent modifications in systems and installations.

Because of the additional joints, installing this type of panel may take more time, but it offers high flexibility in design.

This type of panel is produced and installed as a continuous, seamless structure throughout the manufacturing and installation process. The continuity feature of these panels eliminates joints and gaps between them, ensuring complete and effective thermal and acoustic insulation.

Continuous panels are highly suitable for use in external and internal walls of industrial, commercial, and residential buildings that require strong insulation. Installation of this type of panel is also fast and easy, as its continuous design minimizes the need for additional joints and fittings.

To provide an accurate proposal and final price, it is essential to know the technical specifications of your project. We recommend consulting with Mammut’s sales advisors beforehand.

By having this information, the process of purchasing Wall Sandwich Panel from Mammut will be simpler, faster, and more reliable. We are with you at every step to help you make the best decision. For precise consultation, contact us now and benefit from the experience of working with one of the largest Wall Sandwich Panel manufacturers in the Middle East.

"*" indicates required fields