Mammut Structures Roof Sandwich Panel

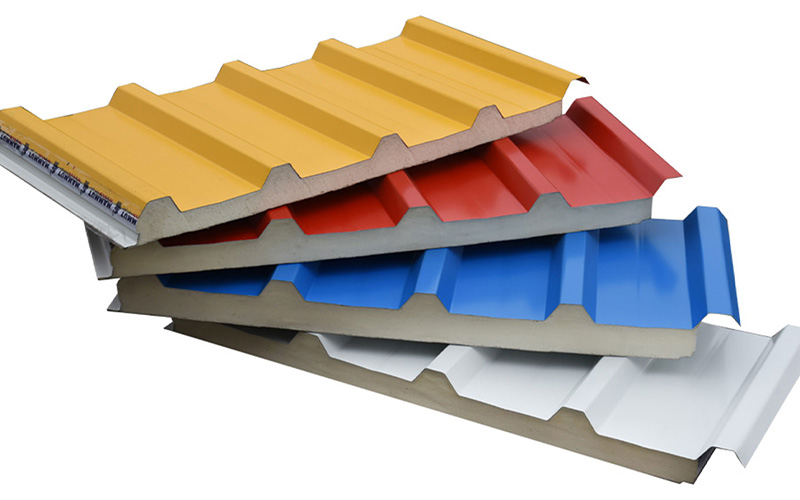

Roof Sandwich Panels are a cutting-edge solution for covering industrial, commercial, and cold storage structures—offering exceptional thermal insulation, soundproofing, and fire resistance. Backed by the latest material technologies, precision manufacturing, and smart design, these panels ensure long-term performance and energy efficiency.

As a leading Roof Sandwich Panel manufacturer with over 30 years of experience, Mammut Industrial Covering Systems leverages fully automated European production lines to deliver a wide range of roof panels with cores made of polyurethane, polystyrene, rock wool, or glass wool. These panels are clad with high-quality materials such as Aluzinc, galvanized steel, or aluminum—ensuring superior resistance to corrosion, moisture, and fire.

If you’re looking to buy high-performance Roof Sandwich Panels with guaranteed quality and reliable delivery, explore the technical details of our available options below.

If you would like to receive a free professional consultation, please fill in your information in the form below. Our experts will contact you as soon as possible to provide the specialized services you need.

Choosing the right roof sandwich panel design plays a critical role in the overall efficiency and durability of a structure. Each model is engineered for specific use cases, climate conditions, architectural styles, and technical requirements.

In this section, we present a professional comparison of the most popular types of roof sandwich panels—including Shadoline, Trapezoidal, and Ardoise profiles—to help contractors, project managers, and industrial buyers make informed, reliable purchasing decisions.

If you’re seeking a roof panel that combines engineering-grade performance with aesthetic appeal, the Shadoline profile is a top-tier choice. Featuring arched and wavy corrugations, it offers not only a refined appearance but also excellent resistance to snow loads, wind pressure, and water penetration.

Technical Specifications:

Ideal for industrial warehouses, sports halls, and large-scale storage facilities, the Shadoline model delivers both beauty and resilience.

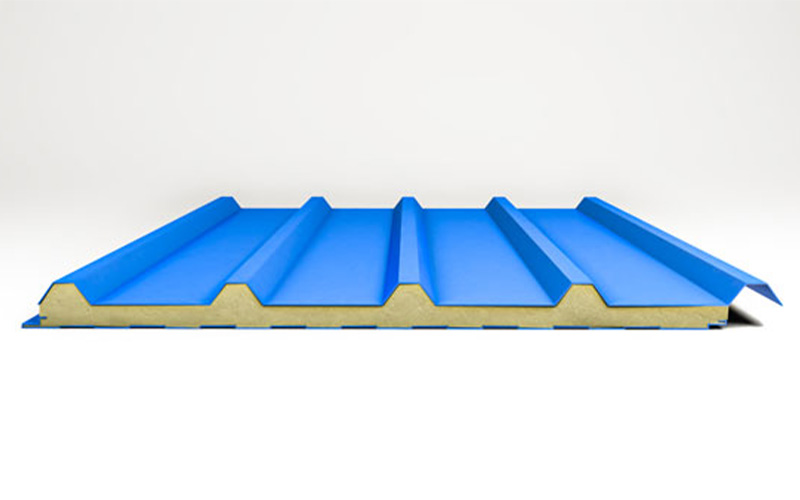

The Trapezoidal panel is one of the most widely used profiles in industrial and manufacturing projects due to its multi-layered geometric design, which enhances structural stability and environmental resistance.

Technical Specifications:

This profile is designed for projects that prioritize mechanical strength, waterproofing, and long service life.

Inspired by traditional stone roofing but upgraded with modern materials, the Ardoise panel offers a classic, premium look—ideal for customers seeking both aesthetic distinction and technical efficiency. Its tiled appearance suits residential villas, exhibition centers, or buildings with unique facades.

Technical Specifications:

The Ardoise panel preserves a traditional roof style while providing the benefits of advanced insulation and fast installation.

Advantages of Consulting with Mammut Experts

When purchasing roof panels, selecting the appropriate core type based on the project’s technical requirements is crucial. Below is a technical comparison of four common types of sandwich roof panel cores, evaluated based on their thermal insulation, acoustic insulation, fire resistance, weight, and cost. Polyurethane offers unparalleled thermal insulation, making it ideal for cold storage facilities. Polystyrene is considered an economical and suitable insulator for projects with a limited budget. Rock wool ensures safety and provides excellent acoustic insulation, making it a great choice for sensitive industries. Additionally, using glass wool insulation keeps the price of sandwich roof panels reasonable for various projects.

|

Core Type

|

Thermal Insulation (λ W/m·K)

|

Sound Insulation (dB)

|

Fire Resistance (min)

|

Approx. Weight (kg/m²)

|

Relative Cost

|

|---|---|---|---|---|---|

|

Polyurethane (PU)

|

0.023

|

25

|

15

|

11–13

|

Medium to High

|

|

Polystyrene (EPS)

|

0.032–0.038

|

20–25

|

5–10

|

8–10

|

Low

|

|

Rockwool

|

0.043

|

27–32

|

60–120

|

15–22

|

High

|

|

Glass Wool

|

0.040–0.045

|

25–30

|

30–60

|

12–18

|

Medium

|

When selecting the right roof sandwich panel for your project, several key factors must be carefully considered—each playing a crucial role in the panel’s overall performance, the longevity of your structure, and long-term maintenance costs. Climate conditions, building type (industrial, commercial, or residential), budget constraints, fire safety requirements, and specific project needs all contribute to making this a highly technical decision.

Evaluating the technical specifications of each panel type and comparing prices is the first step toward making an informed and optimized purchase. Below are the essential factors to consider:

By carefully analyzing these factors and consulting with the experts at Mammut Panel, you can confidently select and purchase the most suitable roof sandwich panel solution for your project.

The price of Mammut roof sandwich panels depends on several factors, including the core type (polyurethane, rock wool, etc.), panel thickness, the type of coating sheet (galvanized, aluzinc, etc.), the final finish, panel length, product customization, and the project location. Weather conditions and the required level of insulation also influence the choice of materials and, consequently, the price.

It is worth noting that in addition to roof sandwich panels, panel & Mammut Structures also offers various types of wall, cold storage, and cleanroom sandwich panels of similar quality. Currently, in the year 1404 (approximately 2025-2026), the price range for roof sandwich panels varies from around 900,000 to 1.8 million Toman per square meter. To receive a detailed proforma invoice and a free consultation, simply send your project information to our experts, and they will recommend the most suitable option based on the technical specifications of your desired roof sandwich panel.

Buying roof sandwich panels from Mammut Structures & panel is not just a simple purchase; it is the beginning of a professional partnership with a manufacturer that lies at the heart of the industry in Iran and the Middle East. At Mammut Structures & panel, we use the most advanced European production lines to create sandwich panels that meet the highest international standards in terms of technical specifications. Every square meter of this product is the result of years of experience, rigorous testing, and real-world needs assessments from civil engineering projects.

With our dedicated consultation, detailed proforma invoices, and the capability for fast delivery even on large-scale projects, you can have peace of mind when choosing the best roof sandwich panel. Contact us—this is where quality, time, and budget all work in your favor.

"*" indicates required fields