Cold Storage Sandwich Panel

Cold Storage Sandwich Panel Mammut Structures

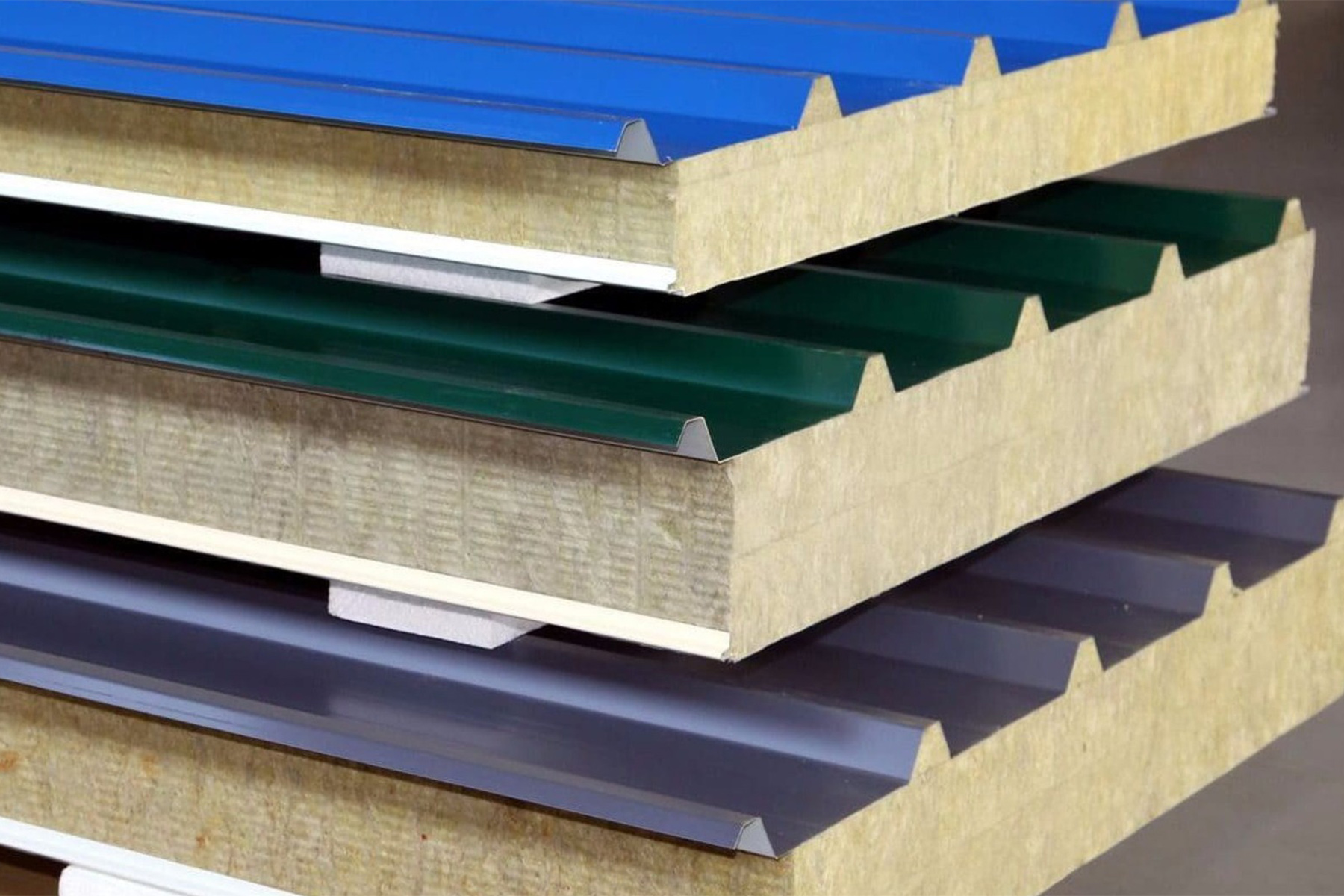

Cold storage sandwich panels are one of the most critical materials for constructing environments with controlled temperature and humidity. Given the need for high insulation against heat, moisture, and contaminants, these panels are typically made from specific materials such as polyurethane, rock wool, and polystyrene.

The structure of a cold storage sandwich panel includes internal insulating layers that help maintain a constant temperature and prevent energy loss. In addition to their use in cold storage facilities, these panels are also utilized in industrial refrigerators and freezers. When purchasing cold storage sandwich panels, factors such as panel thickness, core type, exterior coating, and sanitary standards are extremely important. The price of cold storage sandwich panels is influenced by these factors. A manufacturer of cold storage sandwich panels must adhere to strict standards to deliver durable, high-performance products suitable for specialized conditions.

If you would like to receive a free professional consultation, please fill in your information in the form below. Our experts will contact you as soon as possible to provide the specialized services you need.

Technical Specifications of Cold Storage Sandwich Panel

In this section, the technical specifications table for cold storage sandwich panels is presented with the highest technical precision, in accordance with the requirements of industrial, food storage, pharmaceutical, and sanitary projects. This information is essential for consulting engineers, contractors, and procurement managers, especially when purchasing cold storage panels from reputable manufacturers like Mammut Structures & panel:

|

Technical Feature

|

Value / Detailed Description

|

|---|---|

|

Total Panel Thickness

|

Between 8 to 15 cm (selectable based on internal temperature and environmental conditions)

|

|

Core Insulation Type

|

Polyurethane (PUR), Polyisocyanurate (PIR), Rockwool

|

|

Foam Density

|

40 to 42 kg/m³ (according to EN 14509 standard for cold storage insulation)

|

|

Thermal Conductivity Coefficient

|

Less than 0.023 W/m·K for PUR and PIR foam, approx. 0.035 W/m·K for Rockwool

|

|

Fire Resistance

|

Class B2 (semi-fire-resistant – PUR), Class B1 (fire-resistant – PIR), Class A (non-combustible – Rockwool)

|

|

Locking System Type

|

Hidden Camlock System or Cold Storage Hook Lock with Full Sealing

|

|

Outer Sheet Coating Type

|

Aluzinc, 0.5–0.6 mm thick, corrosion- and decay-resistant

|

|

Inner Sheet Coating Type

|

Aluzinc, galvanized steel, or stainless steel for high-hygiene and frequently washed environments

|

|

Load-Bearing Capacity

|

Up to 250 kg/m², depending on core type and panel thickness, suitable for industrial structures

|

|

Sealant and Air-Tight Gasket

|

EPDM gasket resistant to cold, moisture, and microorganisms, with industrial-grade adhesive

|

|

Customizable Panel Length

|

2 to 14 meters (customized based on structural dimensions of installation site)

|

|

Effective Panel Width

|

96 cm (with tongue-and-groove joint and standard overlap)

|

|

Main Applications

|

Cold storage for food and pharmaceuticals, meat and dairy processing, freezing tunnels, industrial refrigerators

|

Using these specifications when purchasing cold storage panels ensures a technically accurate, durable, and optimized choice that meets all thermal, hygienic, and economic requirements of your project.

Features of Cold Storage Sandwich Panel

- High Thermal Insulation: Made with insulating cores such as polyurethane, polystyrene, or rockwool, these panels offer excellent performance in maintaining internal temperatures and minimizing heat exchange—leading to energy savings.

- Energy Efficiency: Strong insulation helps stabilize interior temperatures and significantly reduces heating and cooling energy demands.

- Quick and Easy Installation: Thanks to their modular structure, cold storage sandwich panels are installed rapidly and cost-effectively, minimizing cold room construction time.

- Moisture and Water Resistance: The waterproof properties of these panels prevent moisture infiltration, thereby reducing the risk of ice formation and maintaining system efficiency.

- Durability and Long Lifespan: Constructed from high-quality materials, these panels offer extended service life with minimal maintenance.

- Design and Application Flexibility: Panels can be tailored to specific project needs—customizable in length, thickness, and core material—enabling use across a wide range of industries.

- Fire Resistance: Panels with rockwool cores provide excellent fire resistance, enhancing safety in fire-sensitive environments.

Types of Mammut Cold Storage Sandwich Panels

PUR Core Cold Storage Panel

Made from rigid polyurethane foam with a density of 40–42 kg/m³, this panel offers excellent thermal insulation and moderate moisture resistance. It is lightweight and easy to install, making it ideal for food, dairy, and produce cold rooms in temperate climates. A cost-effective choice for projects requiring quick execution.

PIR Core Cold Storage Panel

With a denser molecular structure than PUR, PIR foam provides superior fire resistance (up to Class B1) and outstanding performance at low temperatures. This panel is well-suited for industrial, pharmaceutical, and export-oriented cold storage facilities. It meets strict international fire safety and thermal standards, making it ideal for projects with high regulatory demands.

Rockwool Core Cold Storage Panel

Recommended for high-risk environments such as chemical or pharmaceutical cold rooms, this panel offers up to 120 minutes of fire resistance and excellent sound insulation. Though heavier than PUR and PIR panels, Rockwool is the preferred choice where fire safety is the top priority. It complies with EN 13501 fire safety standards.

Stainless Steel Cold Storage Panel

Constructed with 304 or 316 stainless steel sheets, this panel is highly resistant to corrosion, chemicals, and humidity. Ideal for pharmaceutical, laboratory, and hygienic cold rooms requiring frequent washing. Its smooth, non-porous surface prevents bacterial and fungal growth, making it the go-to option where hygiene is paramount.

Let me know if you’d like these structured into a comparison table or brochure-ready format.

Seal-Tight Cold Storage Sandwich Panel

Cold Storage Sandwich Panel with Seamless Joints

(Also known as “Tongue and Groove”)

This type of sandwich panel is specifically designed for cold storage rooms and temperature-controlled spaces. It features a tongue-and-groove interlocking system, allowing panels to tightly lock together without gaps.

The seamless connection significantly enhances thermal insulation performance by preventing air and heat transfer, ensuring maximum energy efficiency and environmental control.

√

pecialized Comparison of Core Materials Used in Mammut Cold Storage Sandwich Panels

One of the most critical steps in purchasing a cold storage sandwich panel is selecting the appropriate insulation core based on environmental conditions, the type of stored product, and the project’s hygiene and safety requirements.

Each common core material used in panel manufacturing comes with specific advantages and limitations, and a clear understanding of them supports more informed technical and economic decision-making.

The following table provides an analytical and specialized comparison of PUR (Polyurethane), PIR (Polyisocyanurate), and Rockwool cores—focusing on thermal performance, fire safety, acoustic insulation, weight, and cost.

|

Features / Core Type

|

PUR (Polyurethane)

|

PIR (Polyisocyanurate)

|

Rockwool (Mineral Wool)

|

|---|---|---|---|

|

Thermal Conductivity

|

Very Low (≤ 0.023 W/m·K)

|

Very Low (≈ 0.022 W/m·K)

|

Average (≈ 0.038 W/m·K)

|

|

Fire resistance

|

Self-extinguishing, Class B2

|

More fire-resistant, Class B1 to B-s1,d0

|

Non-combustible, very high resistance, Class A

|

|

Moisture resistance

|

Good

|

Perfect

|

Relatively low, requires precise sealing

|

|

Sound insulation

|

Average

|

Average

|

Very high

|

|

Density

|

40–42 kg/m³

|

40–45 kg/m³

|

80–120 kg/m³

|

|

Total panel weight

|

Lightweight

|

Lighter than rock wool

|

Heavier

|

|

Approximate price

|

Economical

|

Slightly more expensive than PUR

|

More expensive than both

|

|

Recommended application

|

Standard cold rooms, food industry

|

Pharmaceutical cold rooms, sensitive materials

|

Industrial cold rooms, flammable or sound-sensitive materials

|

This comparison helps consulting engineers, architects, and clients select the best option based on the project’s functional requirements. For more detailed information on pricing, product datasheets, or technical consultation regarding the selection of the appropriate core, please contact the sales experts at Mammut Structures & panel.

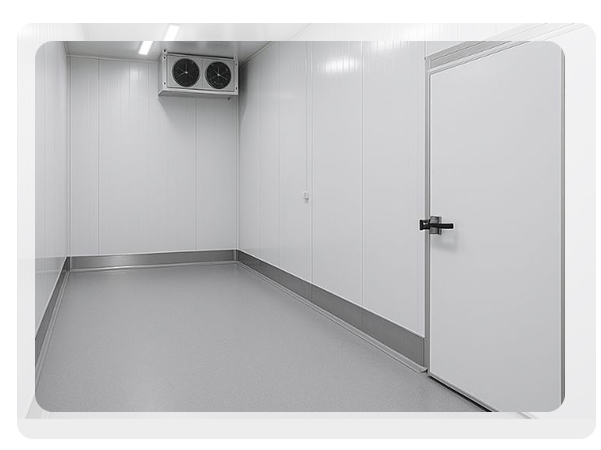

Cold Storage Sandwich Panel Applications

Certainly! Here is the accurate and professional English translation of your text, ideal for use on a website or in an industrial brochure:

Cold Storage Sandwich Panels are widely used in various industrial and food-related projects, including:

Construction of cold storage facilities for food, pharmaceuticals, and dairy products, ensuring product quality

Warehouses for preserving agricultural goods at low and stable temperatures

Meat processing plants and protein-based industries requiring high-performance insulation

Storage areas and distribution centers with controlled temperatures

Cold chain logistics, including containers and warehouses for transport and storage

Using high-quality sandwich panels for cold storage in these applications helps reduce energy loss and extends the lifespan of refrigeration equipment.

If you’d like this styled for a product page, comparison section, or SEO-optimized block, I can help format it accordingly.

Price of Mammut Cold Storage Sandwich Panel

The price of Mammut cold storage sandwich panels is determined based on several key factors. The most important include panel thickness (which directly affects insulation performance), the type of core material (such as PUR, PIR, or rock wool), the outer cladding (e.g., Aluzinc or stainless steel), the required surface area, and the geographical location of the installation site.

On average, the price of cold storage sandwich panels in 2025 ranges from 800,000 to 1.3 million IRR per square meter.

For example, a panel with 10 cm thickness and a PUR core typically falls within the mid-range price segment.

To receive an accurate quotation, get free expert consultation, and choose the best cold storage sandwich panel for your project, contact our specialists today or submit a consultation request form.

Purchase Cold Storage Sandwich Panel Mammut Structures

For accurate selection of a Cold Storage Sandwich Panel, knowing only the thickness or area is not enough. At Mammut Structures, purchasing consultation is based on the type of cold storage (for example, meat, dairy, or pharmaceuticals), the climatic conditions of the project site, the required temperature, and implementation constraints. This means that before any quotation, the real needs of the project will be evaluated. Mammut is not just a manufacturer; we provide engineered solutions. Features of Cold Storage Sandwich Panel Mammut Structures include: the use of high-density PUR or PIR insulation foam to prevent energy loss, panel connections with cold storage sliding locks to eliminate thermal bridging, external Aluzinc or sanitary steel coating for humid and sensitive conditions, precise production according to food and pharmaceutical industry standards, and fast, controlled installation by a trained technical team.

Fill out the consultation form or contact us; because real quality only matters when we think alongside your project from design to implementation.

FAQ

A cold storage sandwich panel is a type of insulated panel specifically designed for use in cold rooms and refrigeration units. These panels consist of two metal sheets and an insulating core, which help maintain low temperatures and optimize energy consumption.

Choosing the best cold storage sandwich panel depends on the type of project, environmental conditions, and your specific requirements. Mammut sandwich panels, known for their high quality and compliance with international standards, are an excellent choice for industrial projects.

The price of cold storage sandwich panels varies depending on the brand, thickness, and type of insulation. For accurate pricing, it is recommended to contact reputable manufacturers such as Mammut Cold Storage Sandwich Panels.

Yes, Mammut cold storage sandwich panels are among the best choices for industrial cold rooms. Thanks to their high resistance to temperature and humidity, these panels are well-suited for use in cold storage conditions.

Using cold storage sandwich panels increases energy efficiency, reduces maintenance costs, and extends the operational life of cold rooms. With excellent insulation, these panels help maintain a stable temperature.

Mammut cold storage sandwich panels are one of the best options for cold rooms due to their use of high-quality materials, long lifespan, quick installation, and low maintenance costs.