Flashing sheets are used as protective coverings for various parts of a building, such as window sills, wall edges, and pitched roofs.

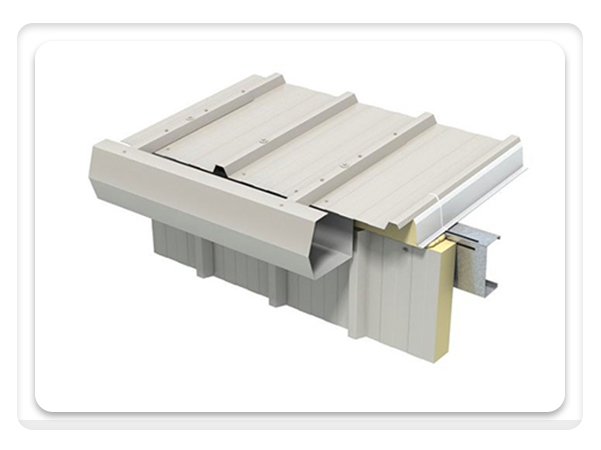

Flashing is a thin, colored metal sheet used for sealing and waterproofing various parts of a structure, such as corners, joints, and edges. The cross-sections of flashings are designed and manufactured based on the specific requirements of each project, and they are typically fastened using rivets. In addition to enhancing aesthetics and structural durability, flashing covers the gaps left from the installation of wall or roof sandwich panels and prevents water and dust infiltration.

Flashing sheets are usually made from the same materials as the ordered sandwich panels, such as pre-painted galvanized steel, Aluzinc, or aluminum. Their typical thickness is 0.4 or 0.5 mm. These sheets are produced in a variety of types—including façade flashing, shaped Shadoline, under-cap, ridge cap, angled corner flashing, stepped, flat, and others—and are used in a wide range of applications.

If you would like to receive a free professional consultation, please fill in your information in the form below. Our experts will contact you as soon as possible to provide the specialized services you need.

In terms of appearance, types of Flushing include L-shaped, Z-shaped, U-shaped, cap, and cover Flushing, each designed for sealing and waterproofing different parts of the building. When purchasing Flushing, paying attention to the profile suitable for the installation location and its material is important to effectively prevent water and moisture penetration.

The Flushing angle is used to cover corners of at least 45 degrees between vertical and horizontal surfaces, such as the junction of a wall with the roof or the floor. This type of Flushing is usually made from galvanized steel, Aluzinc, aluminum, or stainless steel, and is highly effective in preventing water penetration.

| Feature | Description |

|---|---|

| Installation Location | Corner between wall and floor or ceiling |

| Common Material | Aluzinc sheet, stainless steel |

| Typical Thickness | 0.5 to 1 mm |

| Strip Width | 5 to 122 cm |

| Advantages | Easy installation, low cost, durable |

| Disadvantages | Limited use at specific angles |

Step Flushing is used at the intersection of a sloped roof with vertical walls and prevents water from penetrating the wall. The installation of step Flushing is carried out in multiple overlapping layers. It is usually made of aluminum or galvanized steel.

| Feature | Description |

|---|---|

| Installation Location | Connection between sloped roof and vertical wall |

| Common Material | Aluzinc – Stainless steel |

| Typical Thickness | 0.4 to 0.7 mm |

| Common Dimensions | Minimum 5 cm, maximum variable |

| Advantages | Effective waterproofing, prevents leakage |

| Disadvantages | Time-consuming installation, requires expertise |

Crown Flushing is designed to cover the top edge of walls or panels, preventing water penetration from above. It is mostly used at the junction points where panels and walls meet the roof. Common materials include galvanized steel, Aluzinc, and PVC. Other features of Crown Flushing include:

| Feature | Description |

|---|---|

| Installation Location | Top edge of the wall or panel |

| Common Material | Aluminum – Stainless steel |

| Standard Width | 5 to 122 cm |

| Common Thickness | 0.5 to 0.7 mm |

| Special Feature | Prevents rainwater penetration from the top |

U-shaped Flushing or channel Flushing is mainly used for collecting and directing water. This type of Flushing is installed in areas where there is a high risk of water accumulation or penetration. It is usually made of thick galvanized sheets and is easy to install. The technical considerations for purchasing U-shaped Flushing are as follows:

| Feature | Description |

|---|---|

| Installation Location | Under the roof or at the intersection of two surfaces |

| Common Material | Aluminum – Stainless steel |

| Standard Width | 5 to 122 cm |

| Common Thickness | 0.5 to 0.7 mm |

| Special Feature | Directs water towards the gutter |

Counter Flushing is usually used together with the main Base Flushing to provide more reliable waterproofing at the junction of vertical and horizontal surfaces (such as a chimney to the roof). The technical specifications of Counter Flushing are as follows:

| Technical Feature | Description |

|---|---|

| Material | Metal (Aluminum – Stainless steel) or polymer; choice depends on strength and environment. |

| Thickness | Variable, depending on material and application; ensures proper strength and flexibility. |

| Shape | Usually L-shaped; dimensions and angles depend on connection type. |

| Dimensions | Vertical height, horizontal width, branch length; based on connection details and overlap. |

| Installation Method | Screws, rivets, fasteners, sealing; ensuring waterproofing with the wall is important. |

| Coating | Colored or protective coating to increase durability. |

| Standards | Depends on country and application. |

Flat Flushing is a smooth, angle-free metal sheet used as an underlying layer for other Flushing types to enhance waterproofing, or in expansion joints and connection points with flat surfaces. This type of Flushing offers high flexibility in application and can be cut into various shapes. The material of the flat sheet is usually similar to other Flushing types (galvanized steel, aluminum, etc.), and its thickness is determined based on the area of use. The technical specifications of Flat Flushing are as follows:

| Technical Feature | Description |

|---|---|

| Material | Metal sheet (Galvanized, Aluminum, Aluzinc, Copper, Stainless steel) or polymeric materials. |

| Thickness | Usually 0.5 to 3 mm, depending on application and material. |

| Dimensions | Available in rolls or sheets of various sizes and lengths; can be custom-cut. |

| Coating | May have colored, PVC, or other protective coatings to increase durability. |

| Installation Method | Typically secured with special adhesives, nails, or mechanically under other flashings; edge sealing is important for waterproofing. |

Choosing the appropriate material for Flushing ensures the durability and long-term performance of the building’s waterproofing system. When purchasing Flushing, consider the local climate conditions and the required resistance to corrosion. Additionally, the price of Flushing varies based on the type and thickness of the chosen material. The types of Flushing materials are:

Choosing the appropriate type of Flushing depends on the installation location, type of building materials, budget, and aesthetic considerations. In construction projects, a combination of different types of Flushing is usually used to ensure complete waterproofing and protection of the building.

Benefits of Consulting with Mammut Experts

Flushing are important components of a building’s waterproofing system, and their installation location, such as around openings or along different surfaces, directly affects the type of protection they provide. Below, we introduce the types of Flushing based on their installation location:

To ensure you purchase high-performance and durable flashing, it is essential to consider several key points:

Specify the Installation Location: The choice of flashing should be based on its application. For example, wall flashing is structurally different from valley flashing.

Select Materials Suited to Environmental Conditions: For humid or industrial areas, stainless steel or Aluzinc flashing is far more suitable than galvanized types.

Check the Sheet Thickness According to Project Needs: Thicknesses ranging from 0.5 mm to 2 mm are standard and cost-effective for industrial and construction projects.

Ensure Precision in Bending, Angles, and Technical Design: Standardized bends and precise angles are crucial for proper sealing. Be sure to verify this when purchasing flashing.

Review the Technical Datasheet and Request a Warranty: The more complete the technical information, the better your choice will be. Always request this from the seller or manufacturer.

Compare Flashing Prices Based on Quality, Thickness, and Bending Type: Do not focus solely on the price figure; the quality of the material and the execution are more important.

Purchase from a Reputable Manufacturer with a Proven Portfolio: Brands like Mammut or other established flashing companies can provide expert consultation, prompt proforma invoices, and quality assurance.

Ultimately, if you are looking to purchase standard, professional-grade flashing, contact sales consultants before making a final decision. Provide them with your project’s technical specifications so they can recommend the most suitable type for your needs.

If your project is standard and you have a limited timeframe, purchasing ready-made flashing is a good option due to its reasonable price and fast delivery.

However, for special projects with unconventional angles, precise waterproofing needs, or a custom facade design, you should definitely opt for custom-made flashing. In this case, you can select the thickness, material, color, bend angle, and even the type of punching to suit your specific requirements. While the price of custom flashing is higher, it prevents water leakage and facade damage in the long run, offering greater value for the investment.

Get the most accurate Flushing price estimate from the experts at Mammut Structures. To select and purchase Flushing suitable for your project’s needs, simply contact our consultants. Mammut’s technical experts will review the type of structure, area, and installation location to provide the most appropriate Flushing with precise pricing, delivery time, and technical details. The advantages of ordering and purchasing from us include:

For more information or to place an order, simply contact us via the button below (Contact Consultants).

"*" indicates required fields