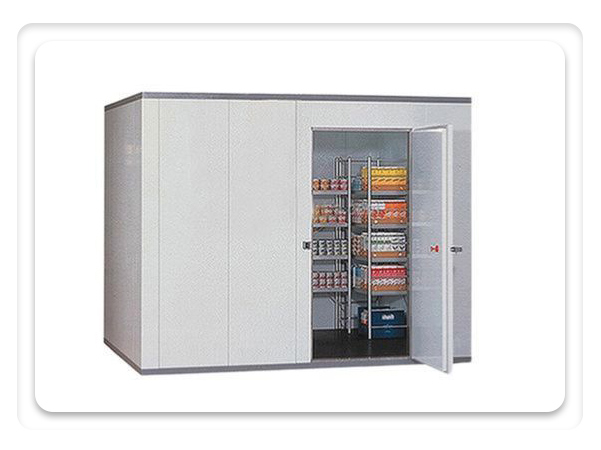

A cold storage container is a space for holding and storing various types of materials with the ability to regulate the temperature from sub-zero to above-zero degrees.

A refrigerated container is an engineered solution for the safe and standard-compliant storage of perishable goods in harsh, mobile, or stationary conditions. Project managers in the food industry, meat and dairy distributors, exporters of pharmaceutical products, and even relief organizations require a structure with precise temperature control, complete insulation, and continuous operation.

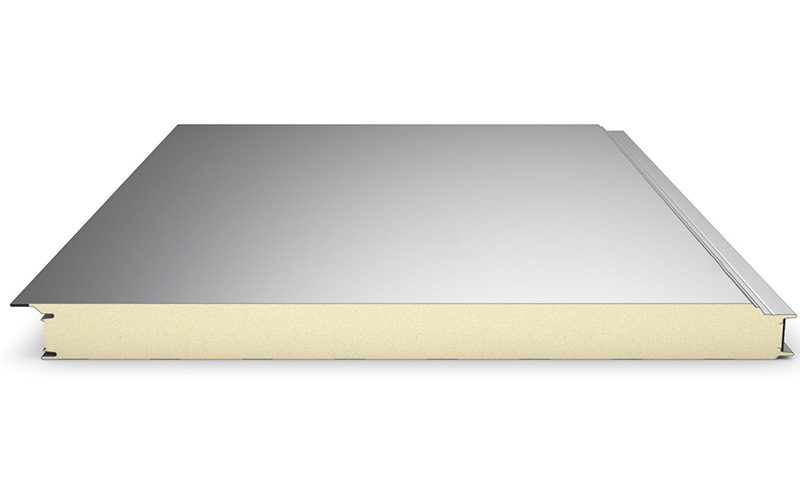

Whether for temporary on-site storage or for in-transit use, containerized cold storage units ensure the security of the cold chain with equipment such as an industrial compressor, high-security doors, sandwich panel walls with polyurethane insulation, and a temperature alarm system. A mobile or stationary refrigerated container—available to order in various sizes and featuring quick installation, portability, and optimal energy consumption—is a professional purchasing choice for critical or operational situations.

If you would like to receive a free professional consultation, please fill in your information in the form below. Our experts will contact you as soon as possible to provide the specialized services you need.

A refrigerated container is a specialized, prefabricated structure with a fully hygienic and insulated design that enables the safe storage of perishable goods in harsh environmental conditions and remote areas. This structure—featuring thermal-insulated sandwich panel walls, reliable industrial compressors, a temperature alarm system, and moisture-proof flooring—is designed for use in the food, pharmaceutical, export, or crisis logistics industries. Key features such as portability, quick installation, optimal energy consumption, and the ability to maintain a constant temperature make these containers a professional choice for purchase in various projects.

Technical Specifications Table for the Refrigerated Container:

|

Feature

|

Technical Description

|

|---|---|

|

Body Type

|

Double-sided galvanized steel sandwich panel with 7-10 cm polyurethane insulation.

|

|

Structural Frame

|

Heavy-duty steel profile with anti-rust coating for stability in harsh conditions.

|

|

Compressor

|

Single or dual-circuit; Bitzer, Danfoss, or similar brands with appropriate power.

|

|

Cooling System

|

Pre-cooling and holding; temperature adjustable between +5°C and -20°C as needed.

|

|

Cold Room Door

|

Anti-slip tread aluminum sheet with complete moisture insulation.

|

|

Power Supply

|

220V or 380V mains electricity; connectable to a generator or UPS.

|

|

Customizable Dimensions

|

Length from 2 to 12 meters; height and width adjustable based on application.

|

|

Portability

|

Features a steel chassis with roof hooks for transport by crane or forklift.

|

|

Alarm System

|

Alerts for temperature increase, power failure, or open door (in smart models).

|

|

Energy Consumption

|

Optimized with thermal insulation; features an A-grade energy efficiency label.

|

|

Applications

|

Food, pharmaceutical, hospital, export industries, construction projects, and emergency relief. Export to Sheets

|

Refrigerated containers are one of the types of Mammut containers and have a wide range of applications. Purchasing a refrigerated container from a reputable manufacturer like Sazeh Pooshesh Mammut ensures quality, an equipment warranty, and on-site project delivery. For urgent or export projects, a specialized pro-forma invoice and technical consultation will make the purchasing process professional and precise.

When selecting a refrigerated container, understanding the various types plays a key role in matching the structure to the product type, climatic conditions, storage duration, and portability requirements. From portable and temporary models to industrial freezer structures and multi-temperature combination units, each type of container is designed based on the specialized needs of the food, pharmaceutical, or export industries. Making the correct choice directly impacts the final cost, product shelf-life, and energy consumption.

The mobile (portable) refrigerated container is one of the most widely used models in projects that require temporary deployment or frequent relocation. This type of structure is typically designed with a reinforced steel frame, complete thermal insulation, secure doors, and the ability to connect to mains electricity or a generator.

For intercity distribution companies, food distribution chains, and relief organizations, purchasing a mobile refrigerated container is considered an optimal solution for maintaining the cold chain under mobile operational conditions.

This type of containerized cold room is designed for the long-term storage of perishable goods in fixed locations such as industrial warehouses, production lines, and logistics bases. The stationary container typically features a robust body, thick thermal insulation, and a dual-circuit cooling system with industrial capacity.

Purchasing a stationary (project-based) refrigerated container from a reputable manufacturer addresses the needs of high-volume projects that require stable cooling and optimal energy consumption.

The refrigerator container (positive temperatures down to -5°C) is suitable for storing products sensitive to temperatures ranging from positive to slightly below zero, such as fruits, vegetables, dairy products, beverages, or flowers.

The structure of this type of container is typically more compact, it has a lighter compressor, and it is usually designed to run on single-phase power.

Purchasing a mobile or stationary refrigerator container is recommended for retail stalls, exhibitions, or short-term distribution centers.

The industrial freezer container (temperatures below -15°C) is designed for storing frozen products such as meat, fish, medicine, or vaccines. This type of structure is manufactured with an industrial cooling system, a smart temperature-increase alarm, insulated doors, and double insulation.

The purchase of an industrial freezer container is typically made by export companies, pharmaceutical distributors, or heavy food industries that require very low temperatures and long-term stability.

For projects that require storing multiple types of products at different temperatures within a single structure, the combination container is considered a professional choice. This model of containerized cold room has several separate compartments, each with an independent cooling system, providing individual temperature control for each section.

Purchasing a combination (multi-temperature zone) refrigerated container creates a significant competitive advantage for multi-product distribution brands, food processing plants, and export businesses.

Benefits of Consulting with Mammut

A detailed comparison of different types of cold storage containers helps professional buyers choose the best option for their projects. In the table below, each model is analyzed based on its application, operating temperature, cooling system, portability, and distinctive technical features.

|

Type of Container

|

Main Application

|

Temperature Range (°C)

|

Cooling System

|

Portability

|

Distinct Feature

|

|---|---|---|---|---|---|

|

Mobile Container

|

Main Skeleton

|

Main Skeleton

|

Main Skeleton

|

Main Skeleton

|

Steel profiles with polyurethane coating resistant to corrosion and moisture

|

|

Mobile distribution, emergency, mobile stores

|

Sandwich panel with a thickness of 5 to 10 centimeters, resistant to heat and sound

|

||||

|

Standard Dimensions

|

From 3×2 meters to 6×3 meters (customizable according to generator capacity)

|

||||

|

+5 to -5

|

Industrial ventilation fans + air vents with dust filters

|

||||

|

Sound Insulation

|

Neoprene, polyurethane insulations, and rock wool insulation in the walls and ceiling

|

||||

|

Light compressor with generator power

|

Anti-slip checkered plate + vibration-damping insulator

|

||||

|

Design Code

|

National Building Code – Chapter 10 + AISC (American Standard)

|

||||

|

Access Ports

|

Full access to the exhaust, fuel, ventilation, wiring, and radiator

|

||||

|

Doors and Windows

|

Industrial anti-theft doors + double-glazed windows for quick inspection

|

||||

|

Accessories/Additional Equipment

|

Internal electrical panel, industrial lighting, fire extinguisher, fuel storage compartment

|

Selecting and purchasing a refrigerated container is a strategic decision for many organizations, distribution companies, and businesses in the food, export, and pharmaceutical industries.

A professional buyer must pay attention to a set of technical and operational points before placing an order to ensure the structure fully complies with the project’s requirements. Below are the most important factors to review when making a purchase:

Required Temperature Range: Depending on the type of product (e.g., medicine, meat, dairy, fruit), specify the temperature that must be maintained (e.g., +4°C, 0°C, or -20°C).

Cooling System: Check the brand and model of the compressor used, whether it is single-circuit or dual-circuit, and if it has smart alarm capabilities.

Insulation Thickness and Type: High-thickness polyurethane insulation leads to lower energy consumption and greater temperature stability.

Container Frame and Body: An anti-rust body, reinforced with a steel frame, increases resistance to moisture, wind load, and impact.

Selecting and purchasing a refrigerated container is a strategic decision for many organizations, distribution companies, and businesses in the food, export, and pharmaceutical industries. A professional buyer must pay attention to a set of technical and operational points before placing an order to ensure the structure fully complies with the project’s requirements. Below are the most important factors to review when making a purchase:

Required Temperature Range: Depending on the type of product (e.g., medicine, meat, dairy, fruit), specify the temperature that must be maintained (e.g., +4°C, 0°C, or -20°C).

Cooling System: Check the brand and model of the compressor used, whether it is single-circuit or dual-circuit, and if it has smart alarm capabilities.

Insulation Thickness and Type: High-thickness polyurethane insulation leads to lower energy consumption and greater temperature stability.

Container Frame and Body: An anti-rust body, reinforced with a steel frame, increases resistance to moisture, wind load, and impact.

The final price of a refrigerated container depends on multiple factors, and a fixed number cannot be quoted for it. In fact, after assessing the customer’s needs and determining the technical specifications, a professional manufacturer provides a formal pro-forma invoice based on the current price of materials and equipment. Below are the most important factors influencing the final purchase cost:

Type of Cooling System: The use of a dual-circuit compressor, foreign brands, or a smart temperature alarm system increases the price.

Degree of Insulation and Panel Type: Using high-density polyurethane sandwich panels increases the manufacturing cost but improves energy efficiency.

Mobility or Stability of the Structure: Mobile containers, due to their modular design, durable connections, and reinforced frames, have a different cost compared to stationary containers.

Additional Features and Customization: Any equipment such as double-layer doors, specialized lighting, industrial flooring, or special ventilation will affect the price.

Order Quantity and Volume: Bulk or high-volume project purchases include manufacturing and shipping discounts.

Transportation and On-site Delivery Costs: Depending on the geographical region, transportation conditions, and crane requirements, this part will have a separate cost.

To provide an accurate proposal and a final price, knowledge of the project’s technical specifications is essential. We recommend having this information ready before contacting Mammut’s sales consultants.

With this information, the process of purchasing a refrigerated container from Mammut will be simpler, faster, and more reliable. We are with you at every step to help you make the best decision. For a detailed consultation, call now and benefit from the experience of collaborating with one of the largest manufacturers of refrigerated containers in the Middle East.

"*" indicates required fields