Sandwich panels combine two durable outer layers with a lightweight core, offering high strength and low weight. Made from EPS, polyurethane or rock wool, they are ideal for walls, roofs, and cold rooms. Their excellent thermal and acoustic insulation, fire resistance, and structural integrity make them a smart choice for efficient building.

Choosing affordable sandwich panels helps reduce energy use, improve safety, and lower maintenance costs. They’re perfect for projects requiring fast installation and reliable insulation. For over 30 years, Mammut has produced sandwich panels using advanced, fully automated production lines. With an annual capacity of 6.5 million square meters, we lead the market in the Middle East, meeting both local demand and export needs.

If you’re looking to buy sandwich panels that combine quality with competitive sandwich panel prices, Mammut offers reliable solutions that meet the highest international standards.

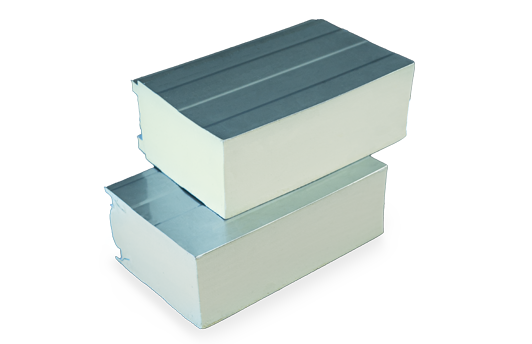

Mammut’s industrial panel solutions offer a modern, lightweight, and durable alternative for commercial, industrial, and cold storage construction. Designed using advanced global technologies and premium materials, our sandwich panels consist of two strong outer steel sheets and a high-performance insulating core—ensuring structural strength, thermal efficiency, and long-term durability.

Energy-Efficient Thermal Insulation: Our energy-efficient panels are engineered with PU, PIR, or QuadCore™ cores, reducing energy consumption by up to 50%. With extremely low thermal conductivity (as low as 0.018 W/m²K), they outperform traditional materials in both heating and cooling efficiency.

Fire Resistance and Safety: PIR-core panels are FM-approved and fire-resistant for up to 2 hours. Mineral Wool cores offer complete non-combustibility, making them ideal for high-risk environments where fire safety is critical.

Quick Installation and Lightweight Design: Weighing just 10–20 kg/m², our panels enable quick installation, cutting project timelines by up to 50% and significantly reducing labor costs.

Long-Term Durability: Mammut panels feature corrosion-resistant coatings like Aluzinc and protective polymer layers, delivering superior resistance to weather, impact, and heavy loads with minimal maintenance.

Effective Acoustic Insulation: Depending on the core type, panels can reduce noise levels by up to 32 dB—ideal for hospitals, conference rooms, and educational buildings.

Smart Investment: While initial costs may vary, a full life-cycle cost analysis proves that Mammut’s cost-effective building materials minimize long-term expenses in energy, labor, and upkeep. Plus, our panels are recyclable building materials, supporting sustainability without compromising performance.

In the manufacturing of sandwich panels, the type of outer sheet plays a vital role in determining the product’s performance, durability, and final application. At Mammut, we leverage premium global materials to offer a wide range of outer sheets—including galvanized steel, aluzinc, plastisol-coated steel, aluminum, and stainless steel—to meet the diverse needs of industrial, commercial, hygienic, and construction projects.

Choosing the right sheet type not only ensures maximum lifespan and superior resistance to environmental factors, but also enhances energy efficiency, visual appeal, and installation ease. Below, we introduce the features, use cases, and advantages of each sheet type to help you buy sandwich panels tailored to your project needs.

Galvanized sheets are made from carbon steel coated with a layer of zinc, providing good corrosion and rust resistance. They are available in thicknesses ranging from 0.4 mm to 0.7 mm, with a tensile strength between 280 to 350 MPa.

Thanks to their affordable price and excellent formability, galvanized sheets are widely used in wall and roof sandwich panels for warehouses, workshops, and industrial buildings. However, in highly humid or corrosive environments, they may offer less durability than other options.

Aluzinc is a steel sheet coated with 55% aluminum, 43.4% zinc, and 1.6% silicon, offering 2 to 6 times more corrosion resistance than galvanized steel.

Capable of withstanding temperatures up to 300°C, aluzinc sheets are an excellent choice for roof and wall panels in industrial and commercial projects located in harsh climate zones. Their aesthetic appeal and extended lifespan make them ideal for custom sandwich panel orders.

Plastisol sheets are made of galvanized steel with a 200-micron thick PVC coating, offering exceptional resistance against chemicals, corrosion, and mechanical damage.

Their smooth surface and wide range of color options make them perfect for food processing, pharmaceutical, and high-humidity environments. Their durability makes them a top choice for long-lasting installations requiring high impact resistance.

Lightweight, corrosion-resistant, and 100% recyclable, aluminum sheets are ideal for cold storage units, prefabricated buildings, and workshops. They offer excellent UV resistance, making them a solid choice for sun-intensive regions.

Aluminum is known for its flexibility, easy installation, and compatibility with clean energy projects. These panels are an excellent solution for those seeking custom sandwich panel orders with environmental benefits.

Stainless steel offers superior resistance to corrosion, heat, and chemicals, making it the go-to material for hygienic environments like medical facilities, food factories, and pharmaceutical labs.

With its glossy, sleek surface and minimal maintenance needs, stainless steel panels are ideal for long-term investments where performance and appearance must be preserved over time.

Choosing the right type of Sandwich Panel plays a decisive role in thermal performance, structural safety, execution speed, and project cost optimization. Sandwich Panel Mammut Structures, utilizing modern production technologies, manufactures a diverse range of Sandwich Panels tailored to various applications, including walls, roofs, cold storage, sanitary spaces, and fire-resistant environments. Below, with a comprehensive introduction to each type, we will examine their features, advantages, and specialized applications to provide a precise, engineered, and cost-effective selection path for construction and industrial projects.

Designed for covering the interior and exterior walls of structures, Wall Sandwich Panels are produced with insulating cores such as polyurethane, polystyrene, rock wool, or glass wool. The outer sheets are made of galvanized steel, Aluzinc, or aluminum, ensuring high resistance to environmental conditions. Wall panels are available for purchase in plain, patterned, and concealed screw types.

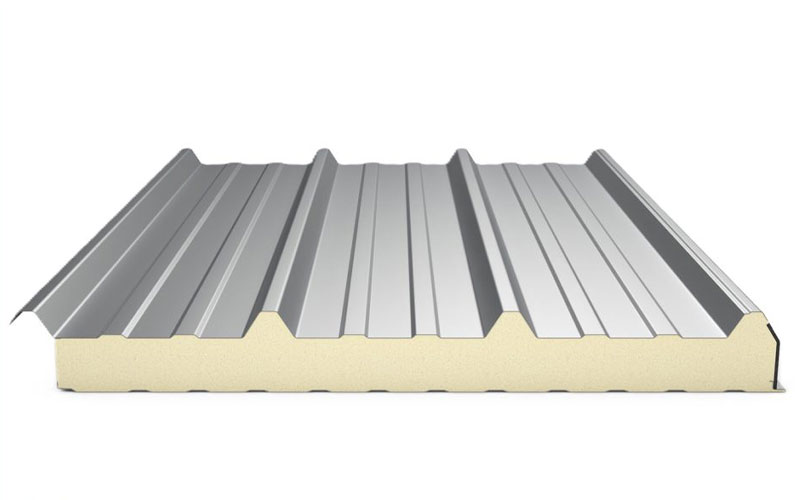

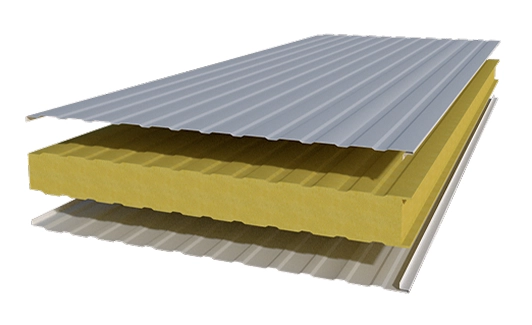

Roof Sandwich Panels are suitable for covering industrial, commercial, and residential roofs. With a special design consisting of a multi-layer structure with an insulating core (such as polyurethane) and two metal layers, they provide effective thermal and acoustic insulation. The insulating cores are similar to those in wall panels, and the outer sheets with corrosion-resistant coatings offer high durability.

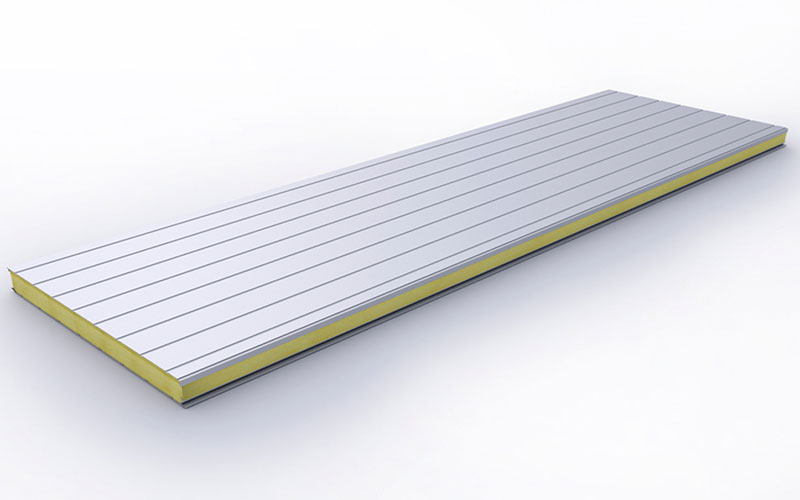

Designed to maintain low temperatures in cold storage and controlled environments, Cold Storage Sandwich Panels feature insulating cores with low thermal conductivity (between 0.022 to 0.028 W/m·K), enhancing energy efficiency. The special connections of these panels ensure complete insulation.

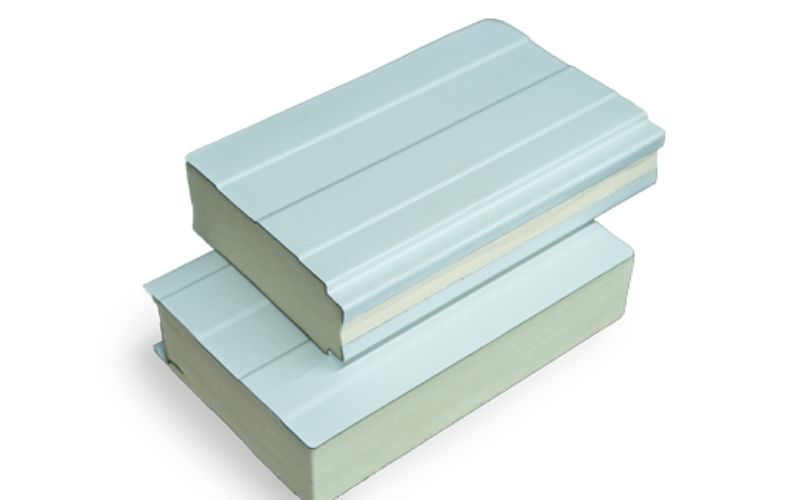

Suitable for environments with high sanitary requirements, such as pharmaceutical and electronics industries, Cleanroom Sandwich Panels have smooth surfaces and are easy to clean, providing the necessary sanitary conditions, such as smooth and seamless surfaces to prevent contamination, chemical and detergent resistance, non-particle generation, and repeated easy washing.

Sandwich Panels with rock wool cores (10 to 24 cm thickness) are non-combustible (A2-s1,d0) and withstand fire up to 240 minutes (walls) and 180 minutes (roofs). This feature is certified by global standards such as FM Approvals. Fire-resistant panels with densities of 90 to 110 kg/m³ provide excellent thermal insulation (U-value up to 0.17) and sound insulation up to 32 dB, making them the optimal choice for buildings where fire safety is critical.

Decorative Sandwich Panels are available in various designs such as wood, stone, glossy metals, modern textures, and custom colors, allowing the creation of unique and attractive interior and exterior facades. These panels are used in modern and classic building facades, commercial, office, and residential interior decoration, stylish partitioning, and constructing special decorative elements, offering both aesthetic appeal and insulating properties.

The choice of sandwich panel color is typically based on the client’s preference and, in some cases, aligned with the client’s corporate color scheme. Occasionally, roofs are covered using two different colors. However, the most commonly used colors are those shown in the image below.

The foam of a Sandwich Panel is its middle layer and core, which is injected between two metal sheets using a foam injection machine with varying densities. It can be considered the reason behind many of the unique features of a Sandwich Panel. For instance, the type of Sandwich Panel foam determines its thermal insulation performance. Other characteristics, such as fire resistance, are also determined by the type of Sandwich Panel foam. Therefore, selecting the appropriate type of Sandwich Panel foam according to the application and project location is of great importance.

Polyurethane foam (PUR/PIR) with a closed-cell structure provides highly effective thermal and acoustic insulation. This foam is produced in two types: PUR (flame-retardant) and PIR (non-combustible). PIR type has self-extinguishing properties and higher fire resistance. Due to its lightweight, high moisture resistance, and water repellency, Polyurethane foam is used in projects requiring high thermal and acoustic insulation, such as cold storage facilities and industrial halls.

Polystyrene foam or EPS (Expanded Polystyrene) is a lightweight and cost-effective material used as thermal and acoustic insulation in Sandwich Panels. This foam has an open-cell structure and lower fire resistance compared to other foams. However, due to its affordable price and light weight, it is used in projects with limited budgets and moderate insulation requirements, such as temporary buildings and warehouses.

Rock Wool foam is made from mineral fibers and has very high fire resistance. This foam can withstand temperatures up to 1000°C and also provides excellent acoustic insulation. Rock Wool foam is used in projects that require high fire resistance and sound insulation, such as control rooms and conference halls.

Glass Wool foam is made from glass fibers and provides suitable thermal and acoustic insulation properties. This foam is lightweight, flexible, and has good fire resistance. Glass Wool foam is used in projects that require thermal and acoustic insulation with low weight, such as office and residential buildings.

The foam materials used in the sandwich panels by Mammut Structures undergo multiple rigorous testing stages to verify compliance with relevant standards. Upon successful completion, certification is issued based on the test results. You can review the certificate by clicking the link below:

It should be noted that in addition to the type of coating, the weight and thickness of the coating are also of great importance. According to standards, the weight of the Aluzinc or galvanized metal coating should not be less than 100 grams per square meter. It is important to mention that the higher the coating weight, the greater the corrosion resistance will be. This level of coating protects the sheet against environmental corrosive factors such as humidity and rust, thereby increasing the lifespan of the sheet and consequently the Sandwich Panel product.

The price of Sandwich Panels varies depending on the type of materials and the specific features of each model. However, price is only one of the factors that should be considered when choosing a Sandwich Panel. Below, we examine the factors that affect the selling price of Sandwich Panels to help you make the best decision.

Core Type: Sandwich Panels are produced with different cores such as polyurethane, polystyrene, rock wool, and PIR, each offering distinct characteristics that influence their prices. Generally, polyurethane cores are more expensive due to their excellent thermal insulation, while panels made from polystyrene or rock wool are usually more economical.

Thickness and Dimensions: Panels are manufactured in various thicknesses, typically ranging from 50 mm to 100 mm. The greater the thickness, the higher the price, as thicker panels provide better insulation performance.

Sheet Material: Galvanized steel, Aluzinc, and aluminum sheets are among the most common options used for covering Sandwich Panels. Aluzinc and aluminum sheets have higher resistance to corrosion and weather conditions, which makes their price higher.

Customization and Special Applications: In specific projects such as cold storage facilities or cleanrooms, there may be a need for panels with special properties, such as high resistance to temperature and humidity, which come at a higher cost.

Although the initial cost of purchasing Sandwich Panels may be higher compared to other options, their long-term economic advantages are remarkable. Reduced energy consumption, long lifespan, and minimal maintenance requirements lead to significant cost savings over time.

Selecting and purchasing a Sandwich Panel is not just a technical decision; it is a strategic choice to ensure construction quality, energy efficiency, and project durability. To make a reliable and cost-effective purchase, it is essential to carefully consider the following factors:

Type of Foam (Insulating Core): Foams such as Polyurethane (PUR/PIR), Polystyrene (EPS), Rock Wool, and Glass Wool each perform differently against heat, sound, and fire. For cold storage facilities and spaces requiring high thermal insulation, Polyurethane is recommended. For projects with fire safety requirements, fire-resistant foams like PIR and Rock Wool are better options.

Outer Sheet Material: The type of metal coating used in a Sandwich Panel directly affects its corrosion resistance, weather durability, and aesthetic appearance. Aluzinc, galvanized steel, aluminum, and stainless steel sheets each serve specific purposes. For example, Aluzinc sheets with anti-corrosion coatings and long lifespan are the best choice for humid areas.

Panel Thickness: The thickness of a Sandwich Panel (typically ranging from 4 to 20 cm) is determined based on climatic conditions, application type, and insulation needs. Thicker panels are recommended for cold regions or cold storage, while medium thickness is sufficient for warehouses or standard industrial halls.

Thermal Conductivity: The lower the thermal conductivity (λ), the higher the insulation efficiency of the panel. Mammut panels with QuadCore™ or PIR cores have extremely low thermal conductivity and can reduce energy consumption by up to 50%.

Fire Resistance: It is crucial to consider fire resistance certifications such as FM standards or fire rating class B-s1,d0 for industrial facilities or areas where electrical and thermal safety are of high importance.

Installation and Joints: Sandwich Panels must be installed using standard fittings and waterproof seals to resist moisture, dust, and wind infiltration. Proper installation increases the structure’s lifespan and reduces maintenance costs.

Price Range: The price of Sandwich Panels varies depending on the foam type, sheet material, thickness, and dimensions. Currently, the price range for these products is approximately 866,000 to 1,700,000 Tomans per square meter. A detailed review of technical specifications alongside project budget provides a solid guide for a cost-effective selection.

Ultimately, choosing a reputable brand with a history of industrial production, quality control, and professional after-sales service is the most important part of a successful purchase. Sandwich Panel Mammut Structures, with over 30 years of experience in manufacturing and exporting, has consistently been among the leading suppliers of Sandwich Panels that meet international standards.

Over 30 years of production experience

Trusted by contractors across UAE, Oman, Iraq, Turkmenistan, and Afghanistan

In-house manufacturing with certified quality control

Professional after-sales support

Proven success in regional logistics, cold storage, and heavy-industry projects

Mammut is not just a supplier — we’re your long-term industrial partner. Let’s build smarter, stronger, and more sustainable spaces together.

Over 30 years of production experience

Trusted by contractors across UAE, Oman, Iraq, Turkmenistan, and Afghanistan

In-house manufacturing with certified quality control

Professional after-sales support

Proven success in regional logistics, cold storage, and heavy-industry projects

Mammut is not just a supplier — we’re your long-term industrial partner. Let’s build smarter, stronger, and more sustainable spaces together.

Sandwich panels are suitable for use in various climatic conditions without any limitations. Compared to other construction materials, sandwich panels generate significantly less waste, highlighting their exceptional value as a building material. Additionally, they allow substantially lower heat transfer than traditional materials, effectively preventing energy loss and contributing to the conservation of natural resources.

Frequently asked questions

sandwich panel is a lightweight and insulating building Materials composed of two metal layers with an insulating core layer, such as polyurethane. These panels are commonly used for walls, roofs, and cold storage facilities.

Sandwich panels are a type of lightweight and durable building material composed of two metal sheet layers with an insulating core in between. Their advantages include thermal and acoustic insulation, low weight, quick installation, and high resistance to various harsh weather conditions.

Wall Sandwich Panels: Suitable for both interior and exterior building walls.

Roof Sandwich Panels: Designed for roofing applications with high thermal insulation.

Cleanroom Sandwich Panels: Specifically developed for hygienic and laboratory environments.

Cold Storage Sandwich Panels: Ideal for cold storage facilities and food warehouses.

By contacting Mammut Structures’ sandwich panel suppliers and consultants, you can obtain detailed information regarding pricing, manufacturing timelines, and delivery schedules.

"*" indicates required fields