Prefabricated Homes by Mammut Structures

mammut, the leading manufacturer of prefabricated buildings in the country.

Prefabricated buildings refer to structures whose main sections or modules are produced in a controlled and equipped environment, such as a factory, instead of being built on the final project site. These components typically include walls, roofs, flooring systems, windows, doors, and even complete modules that are pre-fitted with plumbing and wiring.

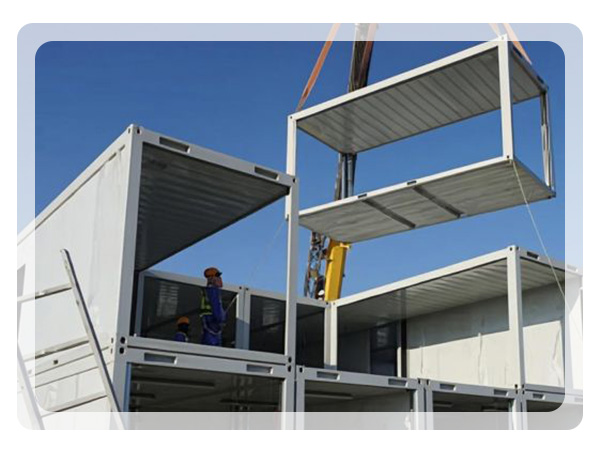

After precise and supervised production in the factory, these parts are transported to the construction site where they are assembled with high speed and accuracy, much like pieces of a puzzle. In some smaller projects, the entire building may even be produced as a single unit in the factory and transported to its final location.

If you would like to receive a free professional consultation, please fill in your information in the form below. Our experts will contact you as soon as possible to provide the specialized services you need.

Speed of Construction

Reduced Energy Waste

Environmentally Friendly

Design Flexibility

Increased Usable Space

Earthquake Resistant

Portability

Cost Reduction

The integration of components produced in a factory environment is as follows:

Modular (Volumetric) System: In this approach, complete, three-dimensional sections of the building, known as modules, are fully constructed in the factory. Types of modular systems include four-sided modules, partially open-sided modules, fully open-sided modules, and modules supported by the main structure.

Panelized Systems: In this system, prefabricated walls, floors, and roofs are produced separately as panels in the factory. They are then transported to the project site and assembled there. Types of panelized systems include Structural Insulated Panels (SIPs), Insulated Concrete Forms (ICFs), and Light Steel Frame (LSF) panels.

This classification indicates the degree of prefabrication and integration of components produced in a factory environment:

Modular System (Volumetric): In this approach, complete, three-dimensional sections of the building, known as modules, are fully constructed in the factory. Types of modular systems include four-sided modules, partially open-sided modules, fully open-sided modules, and modules supported by the main structure.

Panelized Systems: In this system, prefabricated walls, floors, and roofs are produced separately as panels in the factory and then transported to the project site for assembly. Types of panelized systems include Structural Insulated Panels (SIPs), Insulated Concrete Forms (ICFs), and Light Steel Frame (LSF) panels.

Hybrid Approaches: This method combines features of both modular (3D) and panelized (2D) construction. For example, modular units might be used for complex spaces like bathrooms and kitchens, while panelized wall and floor systems are used for larger, more open areas.

Complete Buildings: In this method, the entire building is manufactured as a single unit in the factory and then transported to the project site for installation. This approach is typically suitable for smaller, less complex structures.

The features and characteristics of each prefabricated building are heavily dependent on the type of materials used in it:

Sandwich Panel: Due to its excellent insulation properties, light weight, soundproofing, and cost-effectiveness, it is a superior choice. EPS (Expanded Polystyrene) sandwich panels are particularly popular. mammut uses sandwich panels in the construction of various prefabricated buildings and is also a manufacturer of this product.

Light Steel Frames (LSF): These structures are made from lightweight steel and demonstrate high resistance to natural events such as earthquakes and strong winds. LSF buildings can also be produced in multi-story formats. mammut utilizes LSF in the construction of its structures, which have high resistance to various weather conditions, earthquakes, and strong winds.

Wood: It is a cost-effective and sustainable option. Prefabricated buildings with a wood facade are also very popular and offer a lasting beauty. mammut also offers prefabricated buildings with a wood facade as a popular and beautiful option.

Precast Concrete: Pre-made concrete parts and elements provide excellent fire resistance and good insulation.

PVC (Polyvinyl Chloride): The use of polyvinyl chloride sheets and panels is common in the construction of these types of buildings.

Fiberglass: It is used for its light weight, durability, and resistance to moisture and corrosion, and it is also utilized as a wall covering.

The prefabrication method can be used for constructing buildings of any scale and size and has a wide range of applications:

Small Buildings: This includes structures such as portable cabins (conex) and tiny houses. mammut is also a manufacturer of various types of portable cabins, and you can purchase them from us.

Medium-sized Buildings: Such as one and two-story residential and office buildings.

Large and Complex Projects: This category includes large hospitals, hotels, apartments, and educational and medical centers.

mammut has the capability to produce prefabricated buildings on various scales without any project size limitations and can also design and produce high-rise buildings up to 15 stories.

Benefits of Consulting with Mammut Structures

Relying on modern approaches and advanced technologies, mammut’s prefabricated buildings offer a set of outstanding advantages that have made these structures an efficient and economical option in the construction industry. The most important benefits of choosing mammut prefabricated buildings include the following.

High Speed in Construction and Delivery

The process of manufacturing building components in the factory is significantly faster compared to traditional methods. This speed in production, combined with the quicker installation of parts on the project site, leads to a substantial reduction in the overall project execution time, which can decrease the required time by up to 50%. Since production operations in the factory environment are independent of weather conditions, delays caused by unfavorable weather are minimized. This high speed in construction, installation, and commissioning minimizes the financial impacts of time and inflation.

Significant Reduction in Project Costs

mammut prefabricated buildings considerably reduce overall project costs by decreasing the required manpower and saving on construction time. The use of standard, high-quality materials in all production stages also leads to lower maintenance and repair costs in the long run, minimizing the need for periodic upkeep. This comprehensive approach guarantees a very cost-effective price for customers.

Superior Quality and Precise Control of the Production Process

By utilizing the most advanced technologies and applying maximum quality supervision in a controlled factory environment, mammut ensures the highest level of quality for its prefabricated buildings. All components are sent to the project site after undergoing a 7-step production process and a rigorous final quality control check. These buildings are manufactured in full compliance with national and international standards and are meticulously evaluated by mammut quality inspectors across various aspects such as executive quality control, environmental compatibility, and safety. In every project, mammut delivers guaranteed quality and innovation.

Environmental Protection and Energy Consumption Optimization

A significant portion of the materials used in mammut prefabricated buildings is recyclable, which plays a major role in protecting the environment. The ability to relocate and reuse some of these structures helps conserve natural resources and reduce the volume of construction waste. Furthermore, by using insulators like polyurethane and rock wool, which perform far better than traditional materials, mammut prefabricated buildings effectively prevent energy loss and lead to optimal energy consumption.

Infinite Flexibility in Design and Application

These buildings offer extraordinary flexibility in terms of design and can be constructed in various sizes and for diverse applications. Each part of the structure can be customized and produced exactly according to the specific and unique needs of the customers.

Increased Usable Interior Space

The use of walls with superior insulation in mammut buildings leads to a reduction in wall thickness compared to traditional masonry buildings. The result is more usable interior space within the same square footage.

Exceptional Resistance to Earthquakes and Natural Disasters

In the construction of mammut prefabricated buildings, lightweight materials such as mammut sandwich panels and Light Steel Frames (LSF) are predominantly used. This smart choice of materials, along with strict adherence to standard building principles and advanced engineering design, makes the structures highly resistant when facing critical conditions like earthquakes and strong winds.

Portability and Ease of Assembly/Disassembly

Due to their modular design and the use of linear, planar, and volumetric transport methods, mammut prefabricated buildings can be assembled and disassembled in the shortest possible time and can easily be moved to new locations.

Optimal Thermal and Acoustic Insulation

By utilizing advanced insulators, these buildings provide excellent thermal and acoustic performance, which helps increase the comfort and well-being of residents or users.

Feasibility of Implementation in Hard-to-Reach Areas

Due to the prefabricated nature and ease of transporting components, these types of buildings can be constructed and installed in locations where access is difficult or impossible with traditional methods.

Determining the price of a prefabricated building is influenced by numerous factors; however, these structures are generally considered very cost-effective from an economic standpoint. Although at first glance the initial cost of purchasing a prefabricated building may sometimes seem equal to or slightly higher than traditional construction, its true value lies in high efficiency, significant time savings, and the ability to accurately predict project timelines. This time-saving leads to a reduction in overhead costs, facilitates project management, and results in considerable savings over the entire life cycle of the structure. With a transparent and optimized approach, mammut guarantees the best price for prefabricated projects in the year 1404 (2025-2026).

Several factors influence the final price of a prefabricated building, the most important of which are mentioned below:

Type of Primary Material: The choice of construction materials, in addition to affecting the technical specifications and performance of the structure, plays a key role in determining the price. Common materials include wood, PVC, sandwich panels, precast concrete, and Light Steel Frames (LSF). Due to the type of material, the price of a metal structure is considered high compared to other structures.

Dimensions and Area (Square Footage): Construction costs are mainly calculated based on square footage, and as the dimensions of the structure increase, the final price increases proportionally.

Interior Amenities and Equipment: The level of amenities, utilities, and equipment installed in each prefabricated building varies depending on the intended use, the climatic conditions of the region, and the client’s requests.

Transportation and Installation Costs: Transporting the manufactured parts and components from the factory to the project implementation site requires expenditures for transportation and specialized installation.

It is worth mentioning that establishing and developing a prefabricated production unit requires a significant investment in advanced machinery, continuous innovation, and attracting a specialized workforce, which can be challenging for smaller companies. With years of experience and investment in this field, mammut has overcome all these challenges and is ready to provide the best services.

"*" indicates required fields