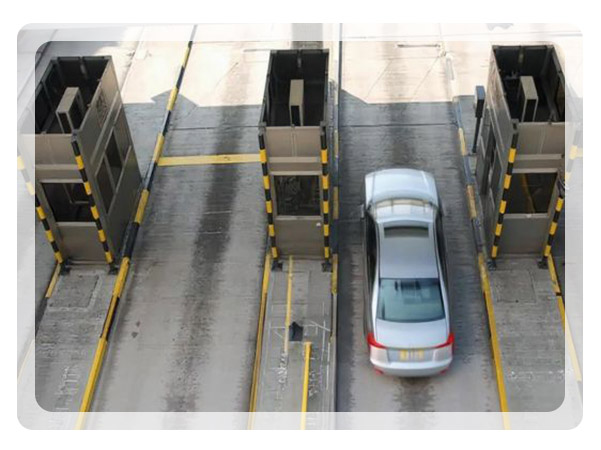

A toll gate cabin is a type of security cabin used for toll collection and control on highways.

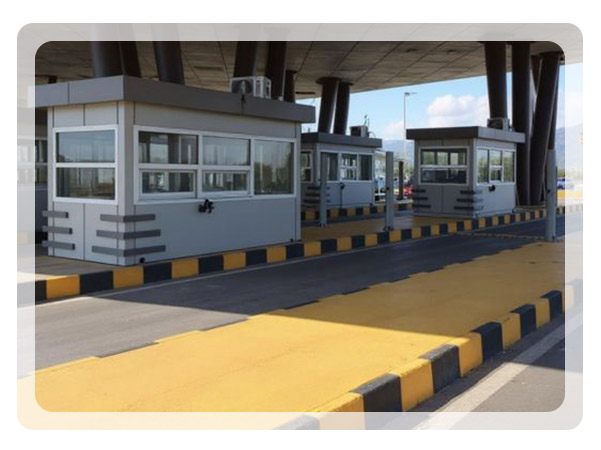

Clients for these types of cabins are often government organizations and private companies active in road construction and tunnel projects, which install toll stations along the routes after project completion. These cabins are usually placed on specially designed platforms intended for this purpose.

The design and dimensions of toll booths may vary depending on regional conditions, climate, and specific project requirements. Generally, these cabins feature a dual-sided structure that allows toll collection from both sides. Pedestrian doors and sliding windows are installed on both sides, and spaces are allocated inside the structure for essential equipment such as air conditioners, work desks, fire extinguishers, and first aid kits.

Due to their roadside placement and exposure to harsh environmental conditions, as well as the need to maintain appropriate interior temperatures for the comfort of toll operators, Mammut Structures uses specialized sandwich panels in the construction of these cabins. This design enhances durability, maintains high quality, and ensures safety and comfort for employees stationed inside for extended periods.

If you would like to receive a free professional consultation, please fill in your information in the form below. Our experts will contact you as soon as possible to provide the specialized services you need.

For the precise design and selection of various types of toll booths for road construction, freeway, and highway projects, it is important to have a detailed understanding of their classification based on construction, design, and installation.

The materials used to build a toll booth have a direct impact on the product’s lifespan, insulation, weight, and final price. Common types of toll booths based on their materials include:

Sandwich Panel Booths: These have walls with polyurethane or polystyrene insulation, 4 to 6 cm thick. Due to their strong thermal and acoustic insulation, they are one of the most widely used options for building managerial toll booths in high-traffic projects.

Composite Sheet Booths: Featuring a modern body with an attractive and luxurious facade, they are suitable for projects where aesthetics and environmental branding are important. Additionally, composite material is resistant to UV radiation and corrosion.

Colored Galvanized Sheet Booths: This is the most economical option among materials. While simple, its durable steel frame makes it suitable for low-traffic areas and temporary projects.

Fiberglass Booths: These are very lightweight, moisture-resistant, and ideal for areas with high rainfall or humidity. At the same time, they require no special maintenance.

Choosing the right material not only reduces maintenance costs but also improves the performance of personnel stationed in the toll booth, thanks to proper insulation and a comfortable interior space.

The internal layout of a toll booth for roads should be designed according to its function and the number of operators stationed inside. The most common types of toll booth layouts include the following:

Single-Operator Booth (Single-Lane): Designed for low-traffic or temporary routes, with limited space for one operator and basic equipment such as a desk, chair, ventilation, and a sliding window.

Two-Operator Booth (Two-Lane): With enough space for two people simultaneously, this is practical for high-traffic routes like highways or intercity toll plazas. They are often designed symmetrically to control both inbound and outbound lanes at the same time.

Booth with Amenities: Suitable for long-term projects, this type includes spaces such as a kitchenette, a restroom, a closet, a rest area, and even a central heating/cooling system. They are highly effective for use as managerial toll booths.

Selecting the appropriate layout increases the work efficiency of operators and reduces personnel fatigue during long shifts.

Types of installation structures for toll road booths include the following:

Portable (Mobile) Booths: These are lightweight and equipped with a metal chassis or base, allowing for relocation by crane or truck. They are suitable for temporary projects or routes where the booth needs to be moved periodically.

Fixed Booths: These feature a heavy frame, a permanent foundation, and are connected to municipal sewage and electrical grids. This type of booth is typically equipped with a sloped roof resistant to rainfall, double-walled construction, and advanced monitoring equipment.

Understanding the required installation type affects the project timeline, transportation, and overall budget.

Benefits of Consulting with Mammut Structures

Before purchasing and selecting a toll booth, several factors must be reviewed to ensure the structure fits the project’s needs. The installation location and the region’s geographical conditions are highly important. For example, in mountainous areas, we recommend using a booth with a double steel chassis and strong insulation. Using durable materials guarantees the booth’s long-term performance. Additionally, you should consider the number of active personnel per shift to determine the appropriate internal facilities, such as electrical wiring, lighting, ventilation, heating, and cooling, based on daily operations.

The structure’s safety is also crucial; an anti-theft system, CCTV cameras, window guards, and a body resistant to impact and decay are essential. Choosing the right material for the body and frame to withstand environmental factors like humidity, temperature changes, and strong winds will increase the booth’s lifespan.

In the process of purchasing a toll booth, choosing a supplier with experience, expertise, and practical support in both design and execution plays a key role in the project’s success. Mammut Structures, with its specialized history in designing and manufacturing various types of toll booths, is a reliable option for contractors, government institutions, and stakeholders in the transportation infrastructure sector. Buying from Mammut is not merely acquiring a structure; it is entering an ecosystem of engineering services, consultation, support, and customization that directly contributes to reducing ancillary costs and increasing the final quality of the project. The advantages of purchasing a toll booth from Mammut include:

Receiving specialized and targeted consultation to select the best design and materials.

A significant reduction in execution time and costs, from design to installation.

More confident decision-making based on the experience of Mammut’s successful projects.

The possibility of custom design, fully aligned with the project’s needs.

Continuous technical support from pre-purchase to final deployment.

Access to professional installation teams and a powerful manufacturing network.

If you are looking to purchase a toll booth with engineering-grade quality, a design compliant with modern standards, and continuous technical support, Mammut is a reliable and specialized option for you.

The price of a toll booth depends on various factors, including its dimensions, type of material (for instance, the use of Mammut sandwich panels), number of windows and doors, internal equipment (air conditioner, electrical system, security cameras), insulation, type of steel frame (single or double), and even the type of doors (bulletproof or standard). Additionally, the complexity of the interior design, lighting, the option for installation on a dedicated platform, and customization capabilities affect the final price.

Due to fluctuations in material costs and the custom nature of each booth’s construction, it is recommended that you contact Mammut’s sales experts to receive a detailed quote. By leveraging modern technology, high manufacturing quality, and a distinguished track record in supplying booths for toll stations, Mammut offers the best price according to the technical specifications. Contact our sales department now for a free consultation and to place your order.

Toll booths are designed with an engineered structure in accordance with industrial standards. The features and technical specifications of the toll booth are as described in the table below:

|

Feature

|

Technical Specifications

|

|---|---|

|

a) Structural Components Walls Flooring

|

Frame made of heavy-duty steel profiles with industrial anti-rust coating Sandwich panels with a thickness of 4 to 6 cm (thermal and acoustic insulation) Waterproof particleboard + high-resistance PVC coating

|

|

b) Electrical and Ventilation Ventilation system

|

Internal wiring with fire-resistant cables, fuse box with RCD protection, energy-efficient LED lighting High-efficiency wall-mounted air conditioner or split unit

|

|

c) Interior Design

|

Ergonomic space for two operators, work desk, equipment storage cabinet, bulletproof sliding window

|

|

d) Insulation and Security

|

ISO-standard thermal insulation, sound insulation for high-traffic roads, anti-theft system for doors and windows

|

Before you buy, carefully reviewing the toll booth’s technical specifications table will help you make a choice that is perfectly suited to your project’s needs.

To provide an accurate proposal and final price, it is essential to know the project’s technical specifications. We recommend having this information ready before contacting Mammut’s sales advisors.

With these details, the process of purchasing a toll booth from Mammut will be simpler, faster, and more reliable. We are with you every step of the way to help you make the best decision. For a detailed consultation, call now and benefit from the experience of working with one of the largest manufacturers of toll booths in the Middle East.

"*" indicates required fields