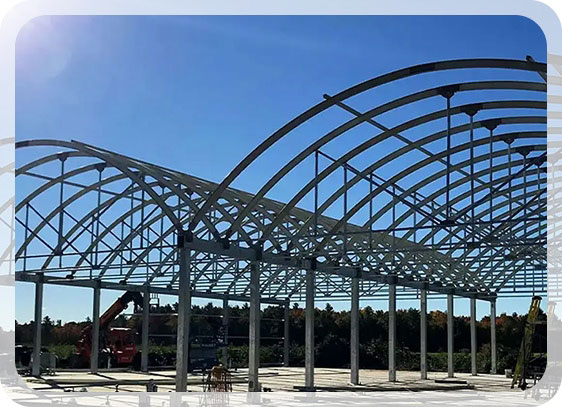

A UBM shed is an engineered solution designed for fast, lightweight, and cost-effective construction of column-free structures. This type of shed is built using galvanized steel sheets that are roll-formed directly on the project site, eliminating the need for a heavy steel frame or welding operations.

UBM sheds are commonly used in projects where construction time, structural weight, and overall cost are critical factors. The price of a UBM shed varies depending on several elements such as total area, sheet thickness, anti-corrosion coating type, and installation location.

Based on project requirements, UBM sheds can be ordered in semi-circular, span-supported, or hybrid designs.

In the following sections of this page, we will cover everything you need to know for purchasing a UBM shed—from technical specifications and construction stages to selecting the most economical option.

If you would like to receive a free professional consultation, please fill in your information in the form below. Our experts will contact you as soon as possible to provide the specialized services you need.

When selecting and ordering a UBM shed, careful attention to the precise technical specifications of this structure is essential. UBM sheds are based on an integrated arched design and do not require internal columns. As such, specific engineering considerations must be reviewed, which we will outline in the following section.

|

Specification

|

Details

|

|---|---|

|

Sheet Type

|

Galvanized or Aluzinc sheet with anti-corrosion coating; thickness from 0.6 to 1.2 mm

|

|

Structure Shape

|

Arched (Arc Shape) with bending radius adjusted based on span and building length

|

|

Span Range

|

6 to 35 meters with no need for interior columns

|

|

Adjustable Height

|

From 3 to 12 meters (up to 18 meters in specific cases)

|

|

Roof Covering System

|

Seamless, integrated, resistant to water, dust, and strong wind penetration

|

|

Snow and Wind Load Resistance

|

Designed according to the National Building Code and regional climate conditions

|

|

Foundation Requirements

|

Strip or pad foundation with simple rebar configuration based on load transfer

|

|

Ground Connection Type

|

Bolts or anchor plates with connection base plates

|

|

Auxiliary Equipment Installation

|

Supports installation of windows, doors, ventilation, lighting, fans, sandwich panels

|

|

Construction Time

|

On average, 50% faster than conventional steel-frame structures

|

|

Structure Weight

|

Lighter than traditional sheds (up to 50% steel reduction in some projects)

|

|

Transportability

|

High; can be disassembled and reassembled at a new location

|

UBM sheds are an engineered and cost-effective choice for fast-track projects requiring lightweight structures with high durability. These features assist engineers, project managers, and investors in making informed decisions based on structural capacity, soil conditions, regional loads, and regulatory standards.

One of the key strengths of UBM sheds is their versatility in a wide range of industrial, military, and commercial applications. Depending on climate conditions, intended use, and project budget, you can customize and order one of the following types for rapid deployment. Understanding the different types of UBM sheds is essential for making sound technical and economic decisions during the purchasing process:

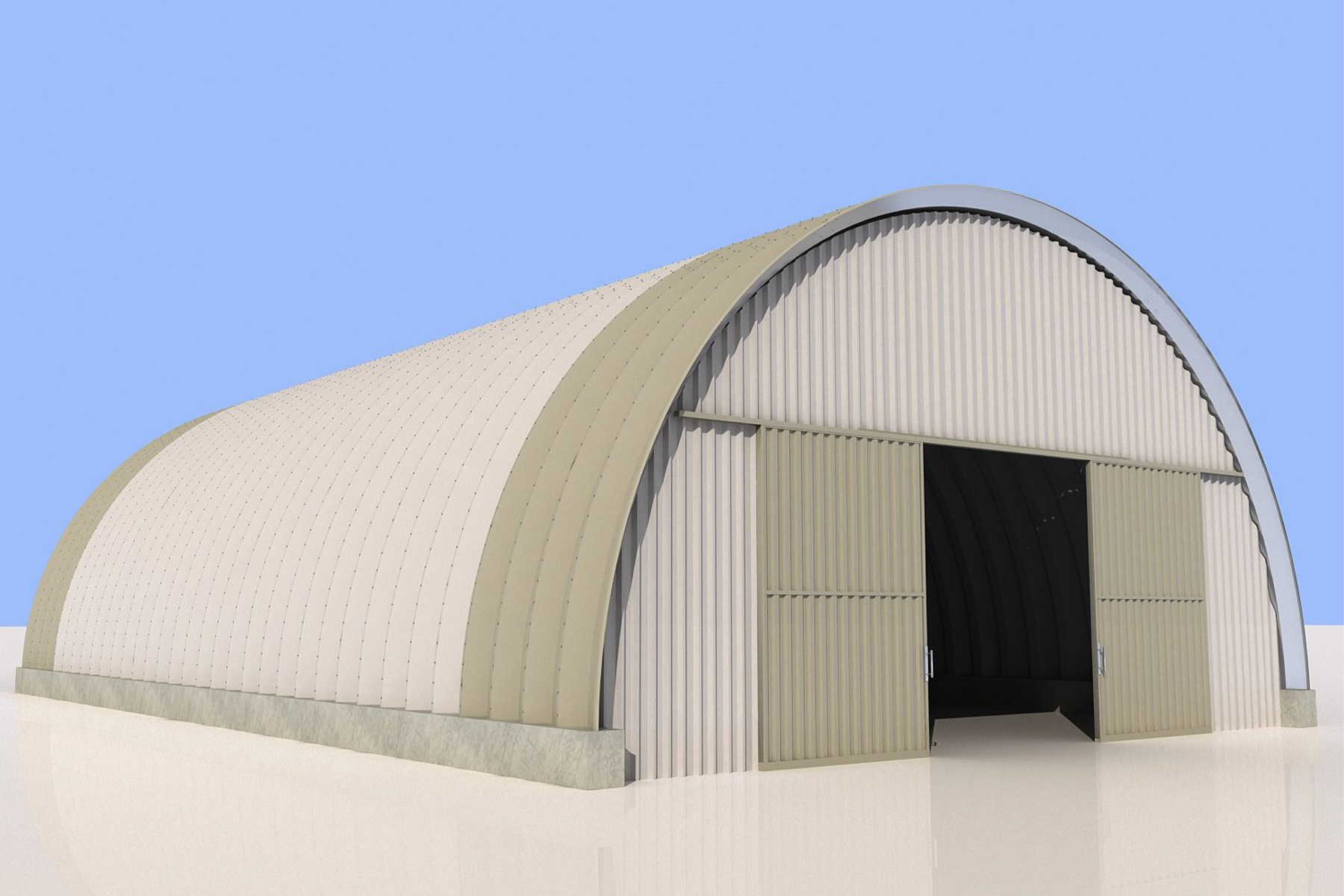

Single Arch UBM Shed:

Suitable for small to medium spans; quick to install, cost-effective, and requires no internal columns.

Double Arch UBM Shed:

Two adjacent spans joined at the crown; ideal for projects with space constraints and a need for increased usable area.

Modified Arch UBM Shed with Vertical Side Walls:

The lower portion of the arch is constructed vertically; suitable for spaces requiring higher side wall clearance.

Custom or Hybrid UBM Shed:

Tailored to specific project needs (e.g., overhead crane installation, ventilation openings, or integration with other structures); fully custom-designed.

The choice of UBM shed type depends on multiple factors such as required span, intended function, local climate conditions, and the project’s execution timeline.

The implementation and construction of this type of shed involve placing one side of the structure on the ground and the other side on a wall. Due to this installation method, this type of UBM shed is also known as a “ground-to-wall structure.”

These sheds are connected to walls or columns on both sides, which is why they are also referred to as “wall-to-wall structures.”

These UBM sheds are known as “ground-to-ground structures” and are supported directly on the ground from both sides. They are highly cost-effective and do not require any side walls for construction or implementation.

The price of a Mammut UBM shed depends on a combination of technical and execution-related factors, each directly influencing the final cost. Key pricing variables include:

The larger the span and the longer the shed, the more material is required, leading to higher construction costs. Additionally, climatic conditions of the installation site (such as high winds, snowfall, or humidity) may necessitate thicker sheets and stronger reinforcement.

UBM sheds with large spans, high elevations, or special features like automatic doors, overhead cranes, or large skylights generally cost more due to their custom design and structural reinforcement. In contrast, sheds with basic functionality, smaller areas, and moderate climate zones tend to be more affordable.

For an accurate cost estimate, it’s recommended to discuss all technical specifications with a consultant before purchase to ensure the shed is tailored to your budget and project requirements.

A UBM steel structure from Mammut should be chosen when construction quality, fast execution, and high durability are your top priorities. At Sazeh Pooshesh Mammut, the construction of this type of structure is carried out using exclusive machinery, precise structural design, and engineering control at every stage.

Globally standardized materials

Specialized consultation before purchase

Fastest production, shipping, and installation

Quality assurance and after-sales services

By submitting a purchase request for a UBM steel structure via the website or receiving a proforma invoice from our experts, you take the first step toward a hassle-free and reliable construction.

Make your decision today; we’ll take care of the rest with precision and expertise.

Advantages of Consulting with Mammut Experts

Arched UBM structures have a wide range of applications, including sports halls, large retail stores, and shopping centers throughout the city. In general, UBM structures are suitable for constructing single-story buildings, and they are also commonly used for parking facilities.

"*" indicates required fields